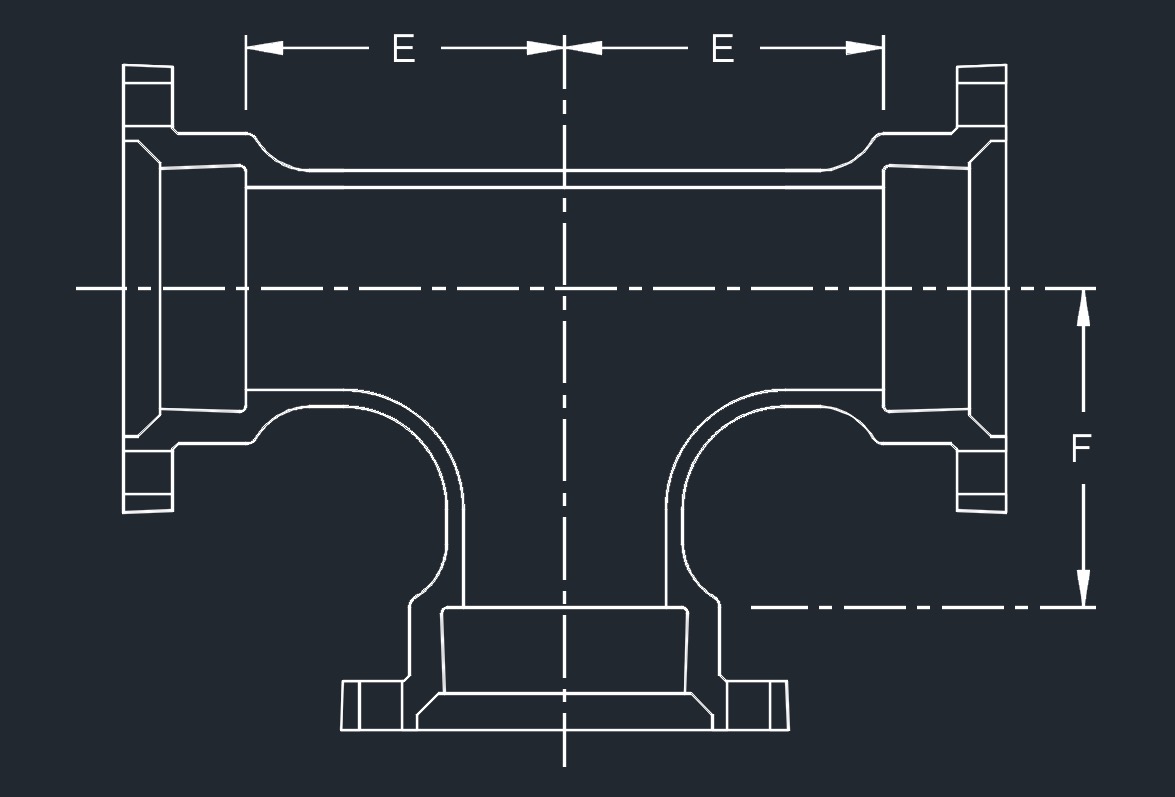

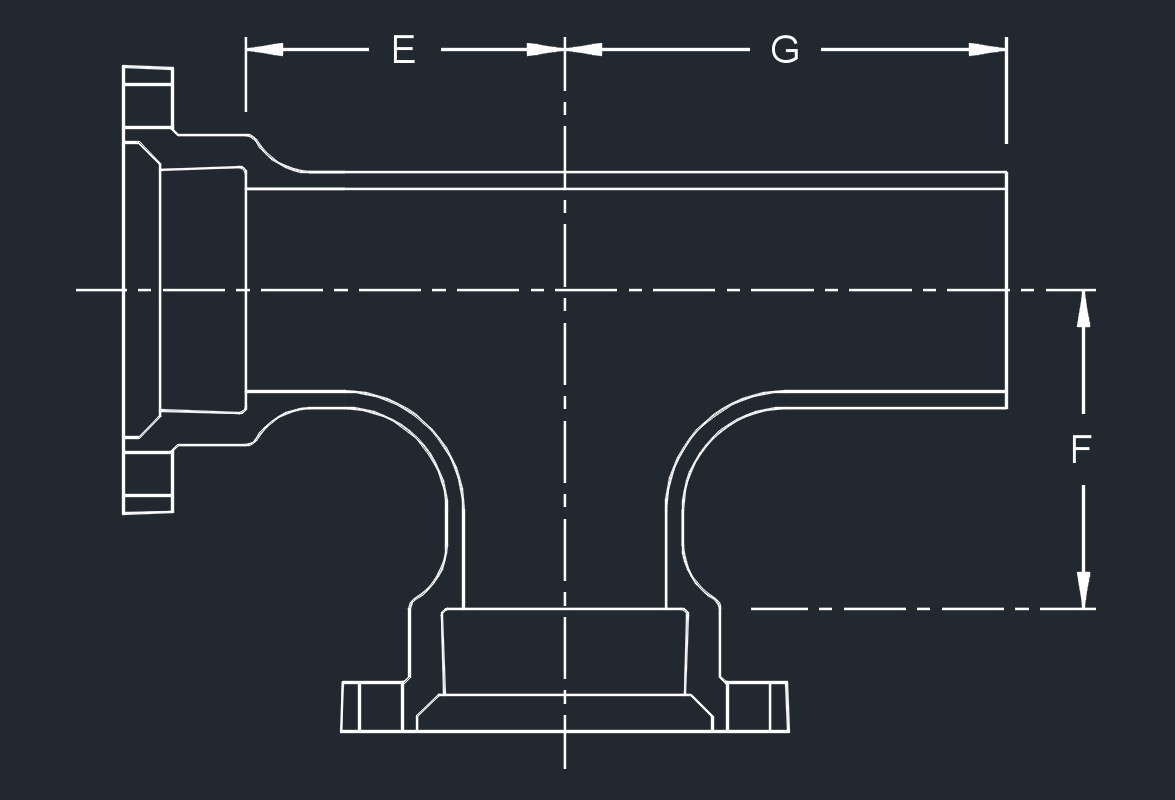

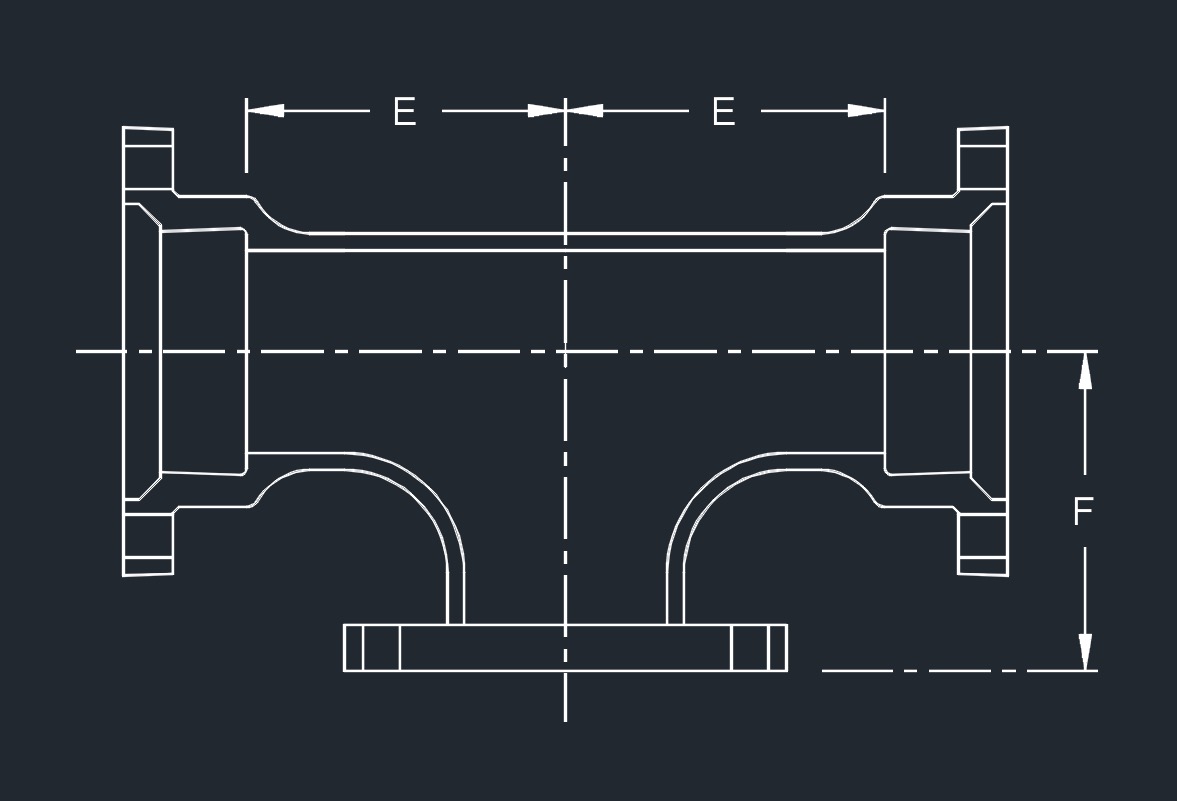

Mechanical Joint Tees - Full Body, AWWA C110, DI (in)

Mechanical Joint Tees - Full Body, AWWA C110, DI (in) | ||||||

|---|---|---|---|---|---|---|

| Pipe Size | Dimensions (in) | Approx. Weight (lb) MJ | ||||

| Run | Run | Branch | E | F | G | |

| * 2 | 2 | 2 | 3.25 | 3.25 | - | 21 |

| * 3 | 3 | 2 | 3.25 | 3.25 | - | 45 |

| 3 | 3 | 3 | 5.5 | 5.5 | 13.5 | 58 |

| * 4 | 4 | 2 | 4.8 | 4.8 | 14.5 | 68 |

| 4 | 4 | 3 | 6.5 | 6.5 | 14.5 | 77 |

| 4 | 4 | 4 | 6.5 | 6.5 | 14.5 | 78 |

| 4 | 4 | 6 | 8.0 | 8.0 | - | 112 |

| * 6 | 6 | 2 | 8.0 | 8.0 | - | 78 |

| 6 | 6 | 3 | 8.0 | 8.0 | 16.0 | 112 |

| 6 | 6 | 4 | 8.0 | 8.0 | 16.0 | 110 |

| 6 | 6 | 6 | 8.0 | 8.0 | 16.0 | 119 |

| 6 | 6 | 8 | 9.0 | 9.0 | - | 158 |

| 8 | 8 | 3 | 9.0 | 9.0 | 17.0 | 155 |

| 8 | 8 | 4 | 9.0 | 9.0 | 17.0 | 157 |

| 8 | 8 | 6 | 9.0 | 9.0 | 17.0 | 175 |

| 8 | 8 | 8 | 9.0 | 9.0 | 17.0 | 199 |

| 10 | 10 | 4 | 11.0 | 11.0 | 19.0 | - |

| 10 | 10 | 6 | 11.0 | 11.0 | 19.0 | 258 |

| 10 | 10 | 8 | 11.0 | 11.0 | 19.0 | 268 |

| 10 | 10 | 10 | 11.0 | 11.0 | 19.0 | 300 |

| 12 | 12 | 4 | 12.0 | 12.0 | 20.0 | 318 |

| 12 | 12 | 6 | 12.0 | 12.0 | 20.0 | 325 |

| 12 | 12 | 8 | 12.0 | 12.0 | 20.0 | 335 |

| 12 | 12 | 10 | 12.0 | 12.0 | 20.0 | 392 |

| 12 | 12 | 12 | 12.0 | 12.0 | 20.0 | 396 |

| 14 | 14 | 12 | 14.0 | 14.0 | 22.0 | 540 |

| 14 | 14 | 14 | 14.0 | 14.0 | 22.0 | 585 |

| * 16 | 16 | 4 | 15.0 | 15.0 | 23.0 | 600 |

| 16 | 16 | 6 | 15.0 | 15.0 | 23.0 | 615 |

| 16 | 16 | 8 | 15.0 | 15.0 | 23.0 | 625 |

| 16 | 16 | 10 | 15.0 | 15.0 | 23.0 | 645 |

| 16 | 16 | 12 | 15.0 | 15.0 | 23.0 | 660 |

| 16 | 16 | 16 | 15.0 | 15.0 | 23.0 | 740 |

| 18 | 18 | 6 | 13.0 | 15.5 | - | 710 |

| 18 | 18 | 8 | 13.0 | 15.5 | - | 674 |

| 18 | 18 | 12 | 13.0 | 15.5 | - | 749 |

| 18 | 18 | 18 | 16.5 | 16.5 | - | 945 |

| 20 | 20 | 6 | 14.0 | 17.0 | - | 849 |

| 20 | 20 | 8 | 14.0 | 17.0 | - | 892 |

| 20 | 20 | 12 | 14.0 | 17.0 | - | 896 |

| 20 | 20 | 16 | 18.0 | 18.0 | - | 1095 |

| 20 | 20 | 20 | 18.0 | 18.0 | - | 1258 |

| 24 | 24 | 6 | 15.0 | 19.0 | - | 1233 |

| 24 | 24 | 8 | 15.0 | 19.0 | - | 1234 |

| 24 | 24 | 12 | 15.0 | 19.0 | - | 1256 |

| 24 | 24 | 14 | 15.0 | 19.0 | - | 1220 |

| 24 | 24 | 16 | 15.0 | 19.0 | - | 1245 |

| 24 | 24 | 18 | 22.0 | 22.0 | - | 1735 |

| 24 | 24 | 20 | 22.0 | 22.0 | - | 1720 |

| 24 | 24 | 24 | 22.0 | 22.0 | - | 1947 |

| 30 | 30 | 6 | 18.0 | 23.0 | - | 2050 |

| 30 | 30 | 8 | 18.0 | 23.0 | - | 2060 |

| 30 | 30 | 10 | 18.0 | 23.0 | - | 2075 |

| 30 | 30 | 12 | 18.0 | 23.0 | - | 2090 |

| 30 | 30 | 16 | 18.0 | 23.0 | - | 2145 |

| 30 | 30 | 18 | 18.0 | 23.0 | - | 2170 |

| 30 | 30 | 20 | 18.0 | 23.0 | - | 2205 |

| 30 | 30 | 24 | 25.0 | 25.0 | - | 2880 |

| 30 | 30 | 30 | 25.0 | 25.0 | - | 2275 |

| 36 | 36 | 6 | 20.0 | 26.0 | - | 2439 |

| 36 | 36 | 8 | 20.0 | 26.0 | - | 2444 |

| 36 | 36 | 10 | 20.0 | 26.0 | - | 2535 |

| 36 | 36 | 12 | 20.0 | 26.0 | - | 2541 |

| 36 | 36 | 14 | 20.0 | 26.0 | - | 2570 |

| 36 | 36 | 16 | 20.0 | 26.0 | - | 2585 |

| 36 | 36 | 18 | 20.0 | 26.0 | - | 2610 |

| 36 | 36 | 20 | 20.0 | 26.0 | - | 2635 |

| 36 | 36 | 24 | 20.0 | 26.0 | - | 2792 |

| 36 | 36 | 30 | 28.0 | 28.0 | - | 3545 |

| 36 | 36 | 36 | 28.0 | 28.0 | - | 3450 |

| 42 | 42 | 24 | 23.0 | 30.0 | - | 3690 |

| 42 | 42 | 30 | 31.0 | 31.0 | - | 4650 |

| 42 | 42 | 36 | 31.0 | 31.0 | - | 4880 |

| 42 | 42 | 42 | 31.0 | 31.0 | - | 6320 |

| 48 | 48 | 24 | 26.0 | 34.0 | - | 4995 |

| 48 | 48 | 30 | 26.0 | 34.0 | - | 5140 |

| 48 | 48 | 36 | 34.0 | 34.0 | - | 6280 |

| 48 | 48 | 42 | 34.0 | 34.0 | - | 8130 |

| 48 | 48 | 48 | 34.0 | 34.0 | - | 8420 |

MJ x MJ x MJ - straight, reducing & bullhead

MJ x MJ x MJ - straight, reducing & bullhead

- * These fittings are not included in AWWA C110/A21.10

- For flange dimensions see Flange - ANSI Class 125, C110, DI

- AWWA C110/A21.10 - Ductile-Iron and Gray-Iron Fittings (3" to 48")

MJ xPE x MJASME B16.1 - Gray Iron Pipe Flanges and Flanged Fittings: Classes 25, 125, and 250 (Flange surfaces shall be faced and drilled in accordance with ANSI Class 125)

MJ xPE x MJASME B16.1 - Gray Iron Pipe Flanges and Flanged Fittings: Classes 25, 125, and 250 (Flange surfaces shall be faced and drilled in accordance with ANSI Class 125)- AWWA C104/A21.4 - Standard for Cement-Mortar Lining for Ductile-Iron Pipe and Fittings for Water

MJ x MJ x FLGAWWA C111/A21.11 - Rubber-Gasket Joints for Ductile-Iron Pressure Pipe and Fittings

MJ x MJ x FLGAWWA C111/A21.11 - Rubber-Gasket Joints for Ductile-Iron Pressure Pipe and Fittings- Ductile iron mechanical joint fittings 3" through 24" shall be rated for 350 PSI working pressure.

- Flanged ductile iron fittings in 24 inch and smaller sizes may be rated for 350 psi with the use of special gaskets.

- MJ - mechanical joint

- PE - plain end

- FLG - flange