Latrolet - ANSI, FCS (in)

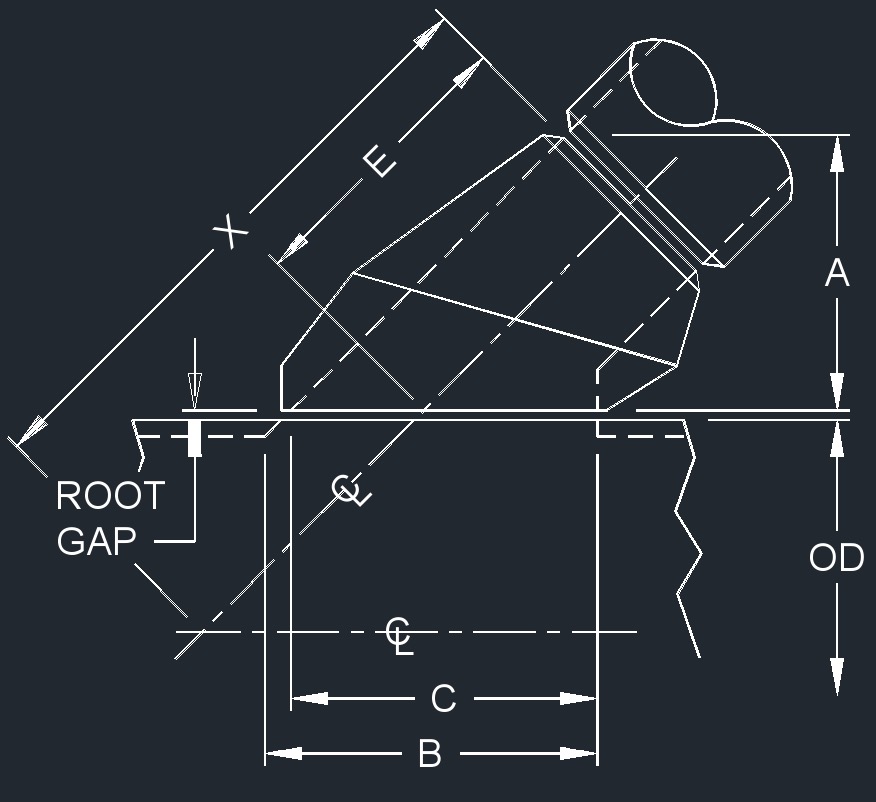

Buttweld Latrolet

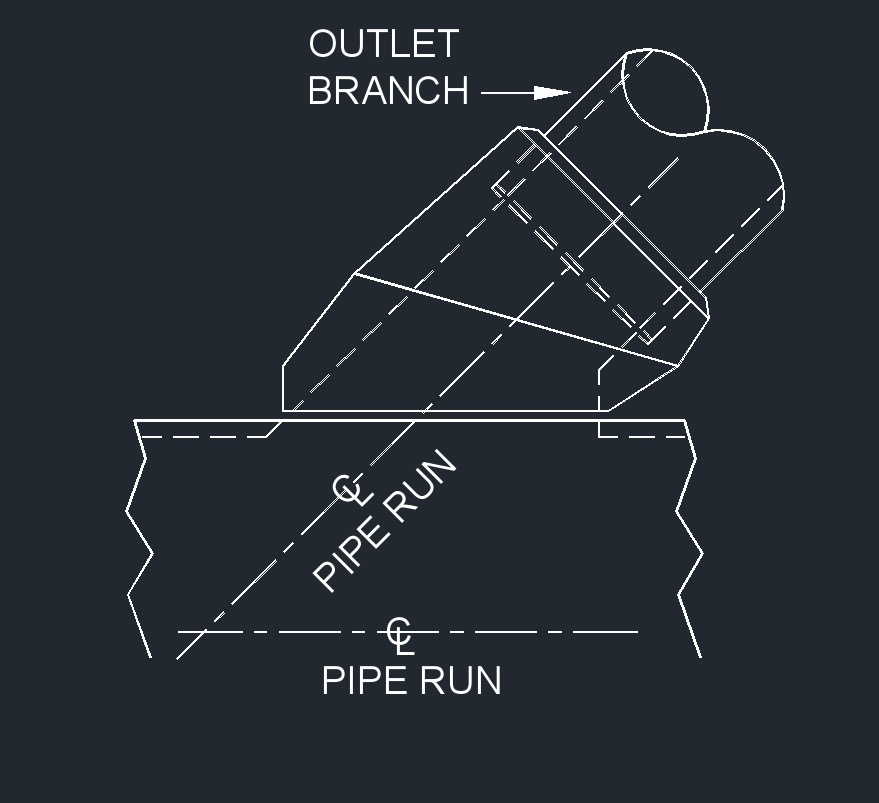

Buttweld Latrolet Socket Weld Latrolet

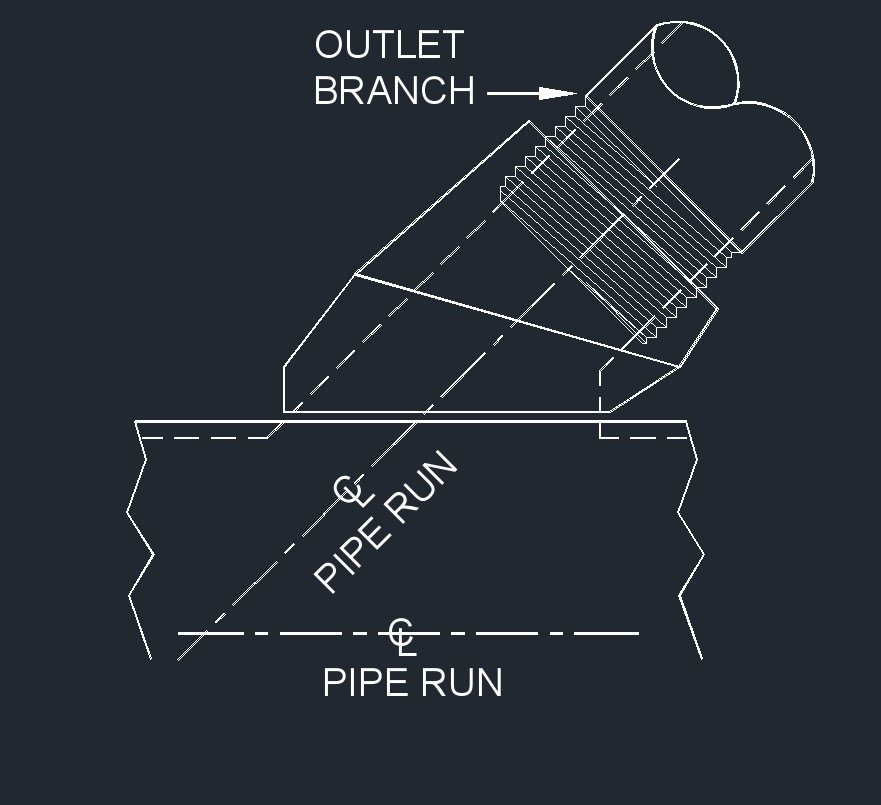

Socket Weld Latrolet Threaded Latrolet

Threaded Latrolet

Latrolet - ANSI, FCS (in) | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Run Pipe Size (NPS) | Outlet Size (NPS) | CL 3000 Threaded and Socket Weld | CL 6000 Threaded and Socket Weld | Sch. Standard and XS Butt Weld | Sch. 160 and XXS Butt Weld | |||||||||||

| A | B | C | E | A | B | C | E | A | B | C | E | A | B | C | ||

| 2 1/2 - 1 1/4 12 -3 |

1/4 | 1 9/16 | 2 11/32 | 1 7/16 | 1 9/16 | 1 9/16 | 2 11/32 | 1 7/16 | 1 9/16 | 1 5/16 | 2 3/32 | 1 7/16 | 1 9/16 | 1 9/16 | 2 5/16 | 1 7/16 |

| 2 1/2 - 1 1/4 12 - 3 |

3/8 | 1 9/16 | 2 11/32 | 1 7/16 | 1 9/16 | 1 9/16 | 2 11/32 | 1 7/16 | 1 9/16 | 1 5/16 | 2 3/32 | 1 7/16 | 1 9/16 | 1 9/16 | 2 5/16 | 1 7/16 |

| 2 1/2 - 1 1/4 12 - 3 |

1/2 | 1 9/16 | 2 11/32 | 1 7/16 | 1 9/16 | - | - | - | - | 1 3/8 | 2 5/32 | 1 7/16 | 1 9/16 | - | - | - |

| 1 1/2 - 1 1/4 5 - 2 12 -6 |

1/2 | - | - | - | - | 1 7/8 | 2 3/4 | 1 3/4 | 1 29/32 | - | - | - | - | 1 13/16 | 2 3/4 | 1 3/4 |

| 1 1/2 - 1 1/4 5 - 2 12 - 6 |

3/4 | 1 7/8 | 2 3/4 | 1 3/4 | 1 29/32 | - | - | - | - | 1 11/16 | 2 17/32 | 1 3/4 | 1 29/32 | - | - | - |

| 2 1/2 - 2 5 - 3 12 - 6 |

3/4 | - | - | - | - | 2 3/16 | 3 1/4 | 2 1/8 | 2 3/16 | - | - | - | - | 2 1/8 | 3 1/4 | 2 1/8 |

| 2 1/2 - 2 5 - 3 12 - 6 |

1 | 2 3/16 | 3 1/4 | 2 1/8 | 2 3/16 | 2 1/2 | 3 21/32 | 2 5/8 | 2 15/32 | 1 31/32 | 3 | 2 1/8 | 2 3/16 | 2 1/2 | 3 13/16 | 2 5/8 |

| 2 1/2 - 2 5 - 3 12 - 6 |

1 1/4 | 2 1/2 | 3 27/32 | 2 5/8 | 2 15/16 | 2 3/4 | 4 7/32 | 3 1/32 | 2 5/8 | 2 9/32 | 3 19/32 | 2 5/8 | 2 15/32 | 2 3/4 | 4 1/4 | 3 |

| 2 1/2 - 2 5 - 3 12 - 6 |

1 1/2 | 2 3/4 | 4 7/32 | 3 1/32 | - | - | - | - | - | 2 15/32 | 3 31/32 | 3 1/32 | 2 5/8 | - | - | - |

| 5 -4 8 - 6 12 - 10 |

1 1/2 | - | - | - | - | 3 3/8 | 5 7/16 | 4 1/8 | 3 5/32 | - | - | - | - | 3 3/8 | 5 3/8 | 4 1/8 |

| 5-4 8 - 6 12 10 |

2 | 3 3/8 | 5 7/16 | 4 1/8 | 3 5/32 | 3 3/8 | 5 7/16 | 4 1/8 | 3 5/32 | 3 3/16 | 5 1/4 | 4 1/8 | 3 13/32 | - | - | - |

| 5 - 4 8 - 6 12 - 10 |

2 1/2 | - | - | - | - | - | - | - | - | 3 5/32 | 5 3/16 | 4 1/8 | 3 5/32 | - | - | - |

| Order to Specific Run Pipe Sizes |

||||||||||||||||

| 3 | - | - | - | - | - | - | - | - | 3 13/16 | 6 1/4 | 4 31/32 | 3 25/32 | - | - | - | |

| 4 | - | - | - | - | - | - | - | - | 4 3/4 | 7 13/16 | 6 7/16 | 4 9/16 | - | - | - | |

- Class 3000 - for use with Sch. 80 pipe.

- Class 6000 - for use with Sch. 160 pipe.

- Dimensions and tolerances in accordance with ANSI/ASME B16.9, ANSI/ASME B16.25 and MSS SP-97.

- Dimensions and tolerances in accordance with ANSI/ASME B16.11

- Specifications for carbon steel forgings in accordance with ASTM A105

- Threads in accordance with ANSI/ASME B1.20.1

- \( X \;=\; ( \frac{OD}{2} + Root Gap ) \;/\; ( .7071 + E ) \)