Flange Facings, ASME B16.5

Flange Facing Types

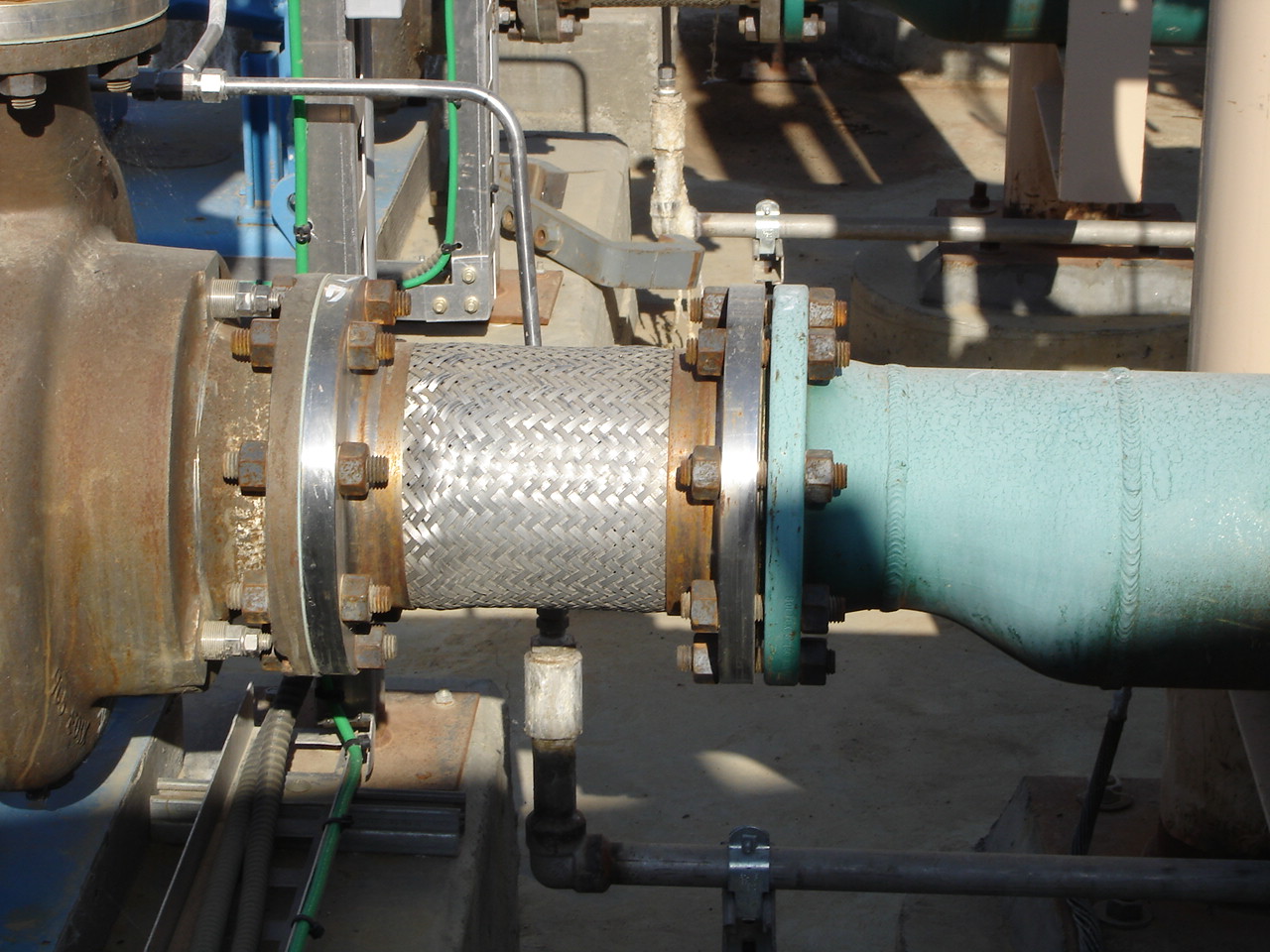

Flat face (FF) - Typically these flanges are used on pump facings or on fiberglass flanges where the torque of compressing the gasket will damage the flange body. They are found in 150# and 300# ratings. Their principal use is to make connections with 125# and 250# cast iron flanges, respectively.

Raised face (RF) - The raised face is the most common used flange face. It is called raised face because the gasket is raised 1/16" and 1/4" above the bolt circle face: 1/16" for 300 lb. and less, 1/4" for 400 lb. and more. The flange facings are machine finished to ANSI/ASME B16.5 requirements.

Ring Type Joint (RTJ) (Class 300 and larger) - This flange is normally used for high pressure gas pipe work. Ring type gaskets must be used on this type of flange.

Tongue and Groove (T&G)

- Small Tongue and Groove

- Large Tongue and Groove

- Small Male and Female

- Large Male and Female

Flange Face Finish

The flange face finish is determined by the standard used and measured as an Arithmetical Average Roughness Height (AARH). An example would be ANSI B16.5 which specifies face finishes within a range 125AARH - 500AARH (3.2 Ra to 12.5 Ra).

Cold Water - It has a mirror like finish. This is made with a wide tool at a high speed which gives a finished surface much like a ground surface. When a surface has this type of finish it is normally used metal to metal, not with a gasket. It is seldom used in the oil, chemical or related industries.

Concentric Serrated - A 90 degree inclined angle tool is used to make the grove. It makes a grove 1/64" deep and 1/32" apart in a concentric circle.

Smooth - This can be made with several different types of tool shapes. No tool markings will appear to the naked eye on the surface. The roughness of the finish is from 125-250 microinch.

Spiral Serrated - This is similar to a stock finish but the difference between them is the way the grove is made. A 90 degree inclined angle tool is used to make the grove. It makes a grove 1/64" deep and the feed is 1/32".

Stock - The surface is created by a continuous spiral groove. The roughness of the finish is from 125 to 500 microinches and is cut with a tool with an approximately 0.06 inches or larger radius.