Overlapping Plate Welds

- See Article - Welded Stress and Strain Connections

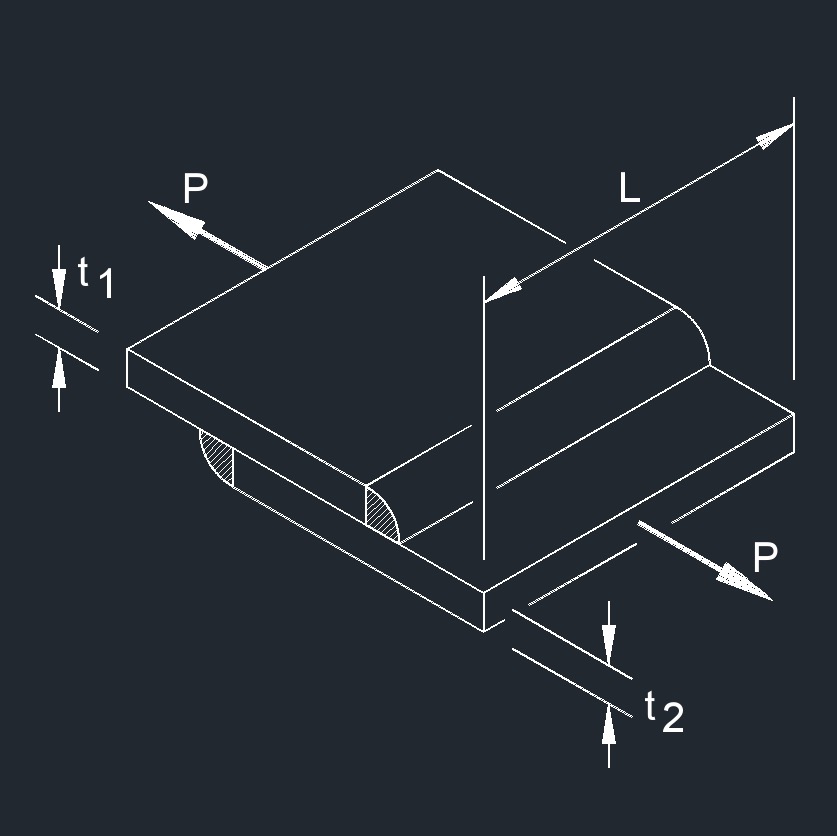

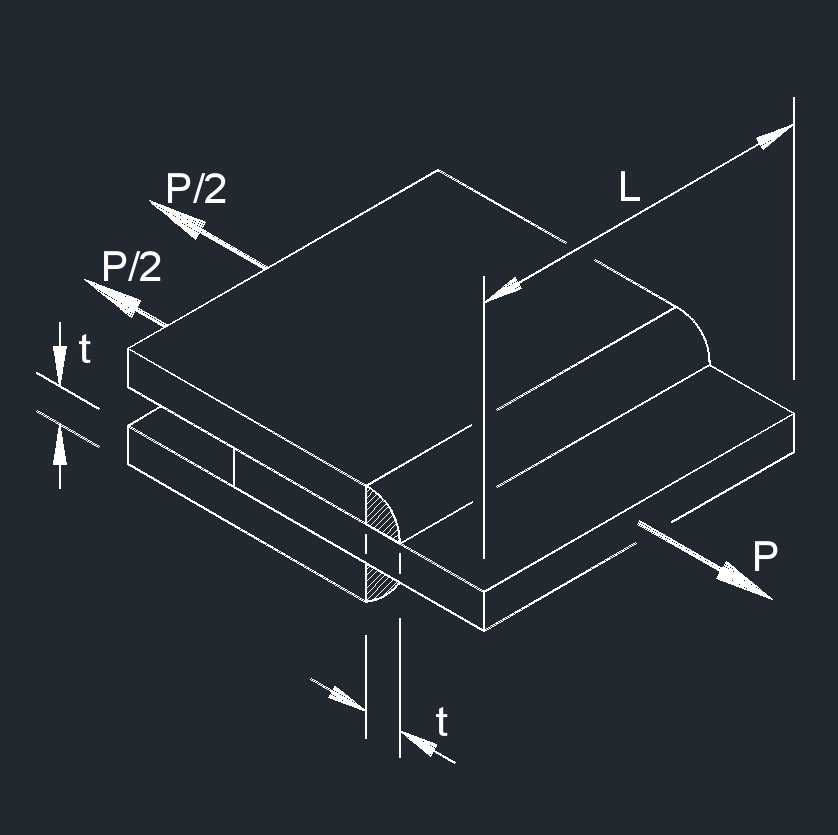

Axial Force on PJP Fillet Weld, 2 Plates formula

|

||

| \( \sigma = \dfrac{ 1.414 \cdot P }{ \left( t_1 + t_2 \right) \cdot L } \) | ||

| Symbol | English | Metric |

| \(\large{ \sigma }\) (Greek symbol sigma) = stress in weld | \(lbf\;/\;in^2\) | \(Pa\) |

| \(\large{ L }\) = length of weld | \(in\) | \(mm\) |

| \(\large{ t }\) = plate thickness / weld thickness | \(in\) | \(mm\) |

| \(\large{ P }\) = total axial force | \(lbf\) | \(N\) |

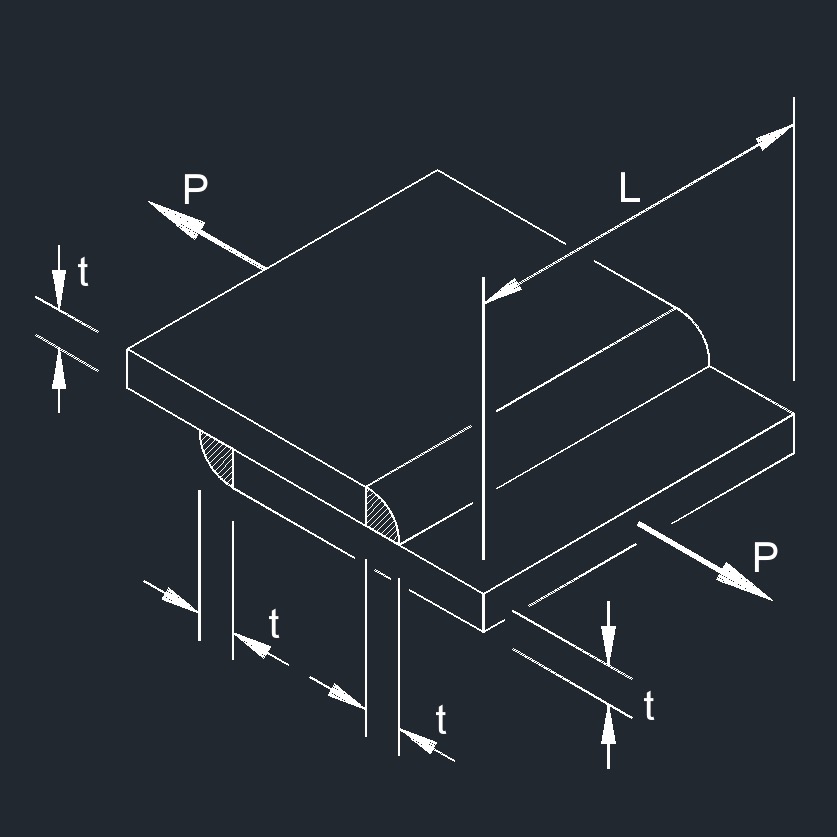

Axial Force on PJP Fillet Weld, 2 Plates Formula

|

||

| \( \sigma = \dfrac{ 0.707 \cdot P }{ t \cdot l } \) | ||

| Symbol | English | Metric |

| \(\large{ \sigma }\) (Greek symbol sigma) = stress in weld | \(lbf\;/\;in^2\) | \(Pa\) |

| \(\large{ L }\) = length of weld | \(in\) | \(mm\) |

| \(\large{ t }\) = plate thickness / weld thickness | \(in\) | \(mm\) |

| \(\large{ P }\) = total axial force | \(lbf\) | \(N\) |

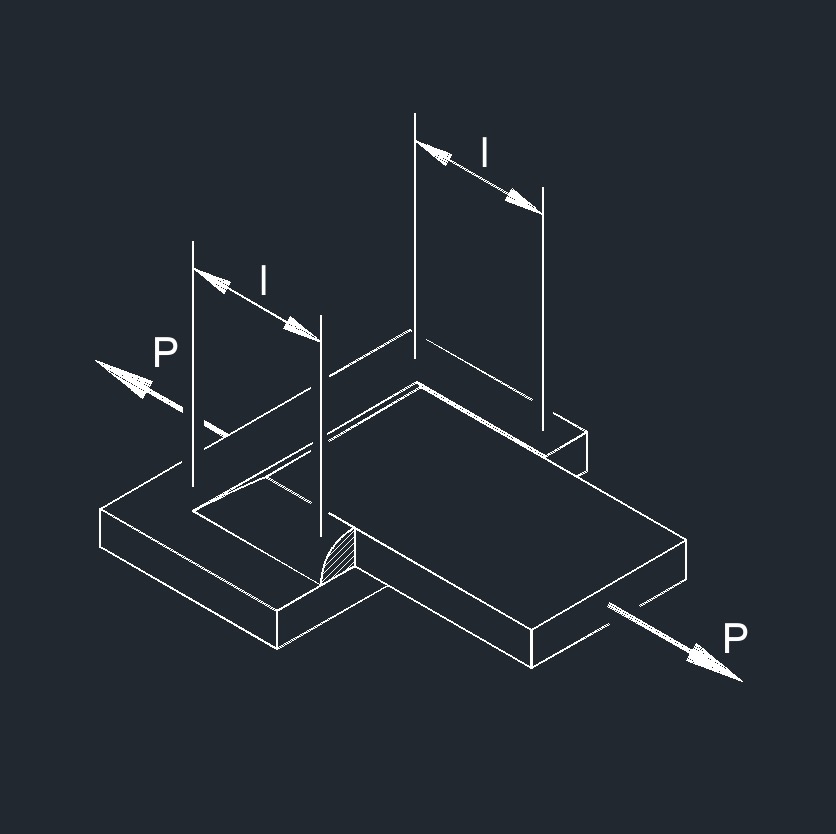

Axial Force on PJP Fillet Weld, 2 Plates, Weld 3 formula

|

||

| \( \sigma = \dfrac{ 0.707 \cdot P }{ t \cdot l } \) | ||

| Symbol | English | Metric |

| \(\large{ \sigma }\) (Greek symbol sigma) = stress in weld | \(lbf\;/\;in^2\) | \(Pa\) |

| \(\large{ l }\) = length of weld | \(in\) | \(mm\) |

| \(\large{ t }\) = weld throat thickness | \(in\) | \(mm\) |

| \(\large{ P }\) = total axial force | \(lbf\) | \(N\) |

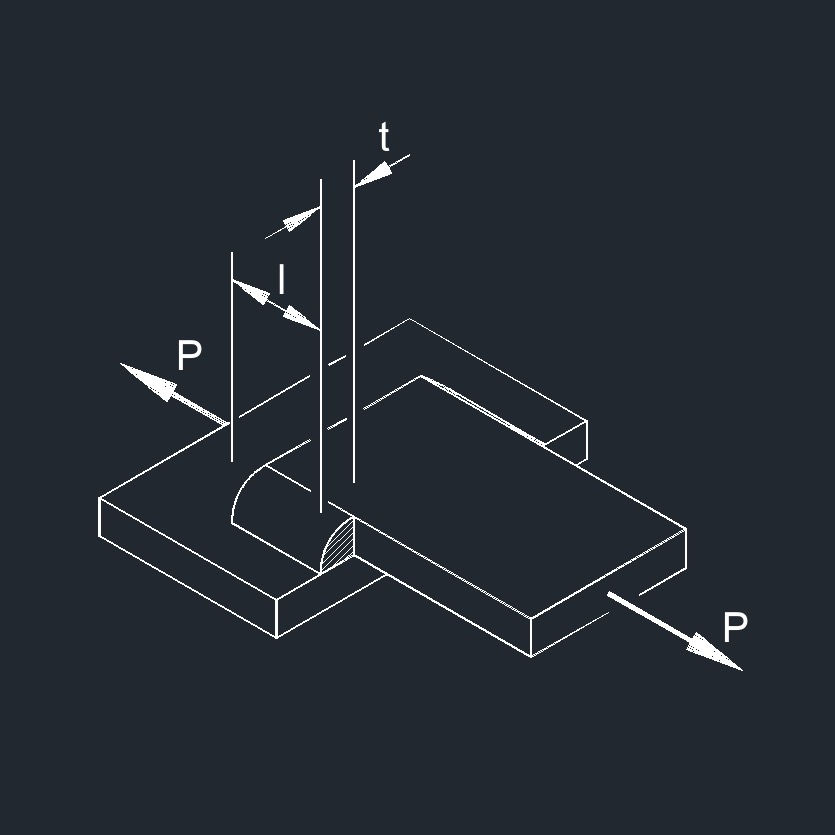

Axial Force on PJP Fillet Weld, 2 plates, Weld 2 formula

|

||

| \( \sigma = \dfrac{ 0.707 \cdot P }{ t \cdot l } \) | ||

| Symbol | English | Metric |

| \(\large{ \sigma }\) (Greek symbol sigma) = stress in weld | \(lbf\;/\;in^2\) | \(Pa\) |

| \(\large{ l }\) = length of weld | \(in\) | \(mm\) |

| \(\large{ t }\) = weld throat thickness | \(in\) | \(mm\) |

| \(\large{ P }\) = total axial force | \(lbf\) | \(N\) |

Axial Force on PJP Fillet Weld, 3 Plates formula

|

||

| \( \sigma = \dfrac{ 0.707 \cdot P }{ t \cdot L } \) | ||

| Symbol | English | Metric |

| \(\large{ \sigma }\) (Greek symbol sigma) = stress in weld | \(lbf\;/\;in^2\) | \(Pa\) |

| \(\large{ L }\) = length of weld | \(in\) | \(mm\) |

| \(\large{ t }\) = weld throat thickness | \(in\) | \(mm\) |

| \(\large{ P }\) = total axial force | \(lbf\) | \(N\) |

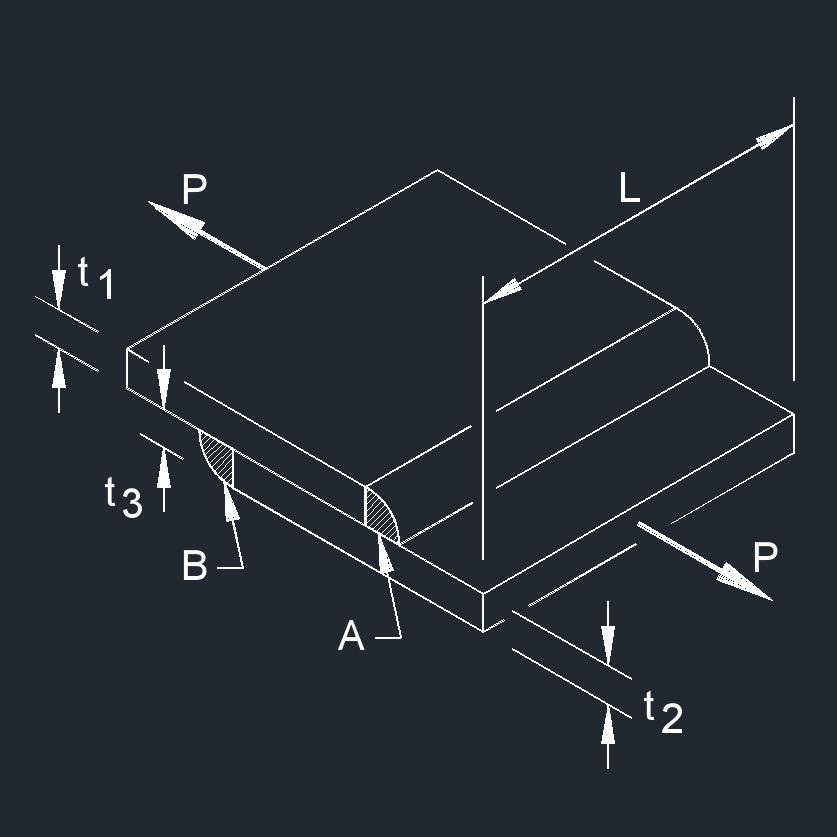

Axial Force on PJP Fillet Weld, 2 Plates formulas

|

||

|

\( \sigma = \dfrac{ 1.414 \cdot P }{ \left( t_1 + t_2 \right) \cdot L } \) (Weld A) \( \sigma = \dfrac{ 1.414 \cdot P \cdot t_2 }{ \left( t_1 + t_2 \right) \cdot t_3 \cdot L } \) (Weld B) |

||

| Symbol | English | Metric |

| \(\large{ \sigma }\) (Greek symbol sigma) = stress in weld | \(lbf\;/\;in^2\) | \(Pa\) |

| \(\large{ L }\) = length of weld | \(in\) | \(mm\) |

| \(\large{ t_1 }\) = plate thickness | \(in\) | \(mm\) |

| \(\large{ t_2 }\) = plate fhickness | \(in\) | \(mm\) |

| \(\large{ t_3 }\) = weld throat thickness | \(in\) | \(mm\) |

| \(\large{ P }\) = total axial force | \(lbf\) | \(N\) |

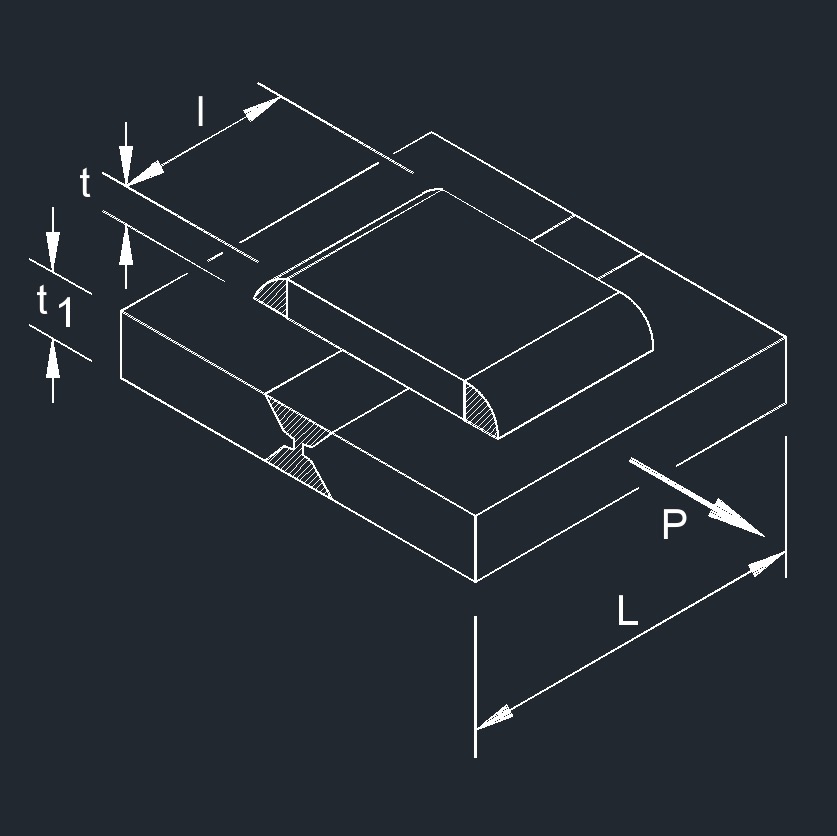

Axial Force on PJP Fillet Weld, 3 Plates formula

|

||

| \( \sigma = \dfrac{ 0.354 \cdot P }{ t \cdot l } \) | ||

| Symbol | English | Metric |

| \(\large{ \sigma }\) (Greek symbol sigma) = stress in weld | \(lbf\;/\;in^2\) | \(Pa\) |

| \(\large{ l }\) = length of weld | \(in\) | \(mm\) |

| \(\large{ t }\) = weld throat thickness | \(in\) | \(mm\) |

| \(\large{ P }\) = total axial force | \(lbf\) | \(N\) |

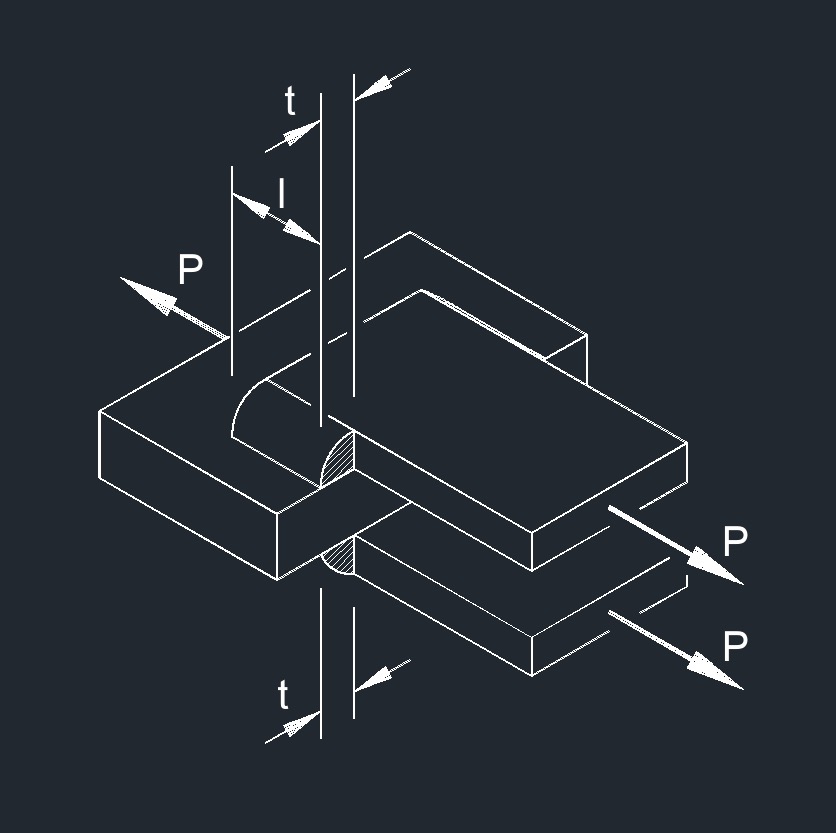

Axial Force on PJP Fillet Weld, 3 Plates formulas

|

||

|

\( \sigma = \dfrac{ 1.414 \cdot P }{ 2 \cdot t \cdot l + t_1 \cdot L } \) (Fillet Weld) \( \sigma = \dfrac{ P }{ 2 \cdot t \cdot l + t_1 \cdot L } \) (Butt Weld) |

||

| Symbol | English | Metric |

| \(\large{ \sigma }\) (Greek symbol sigma) = stress in weld | \(lbf\;/\;in^2\) | \(Pa\) |

| \(\large{ l }\) = length of top plate weld | \(in\) | \(mm\) |

| \(\large{ L }\) = length of bottom plate weld | \(in\) | \(mm\) |

| \(\large{ t }\) = top plate thickness | \(in\) | \(mm\) |

| \(\large{ t_1 }\) = bottom plate fhickness | \(in\) | \(mm\) |

| \(\large{ P }\) = total axial force | \(lbf\) | \(N\) |