Management and Systems Engineering

Safety, Project Management, Engineering, Management and Systems

- See Article - Management and Systems Glossary

| Engineering |

| Management and Systems Engineering |

Management Engineering

Management focuses on organizing, planning, leading, and controlling resources to achieve specific objectives. It's primarily concerned with people, processes, and organizational goals.

Key Points about Management

Leadership - Motivating and guiding teams.

Planning - Defining objectives and creating strategies to achieve them.

Resource Allocation - Managing human, financial, and physical resources effectively.

Problem-Solving - Addressing operational challenges and strategic issues.

Performance Evaluation - Measuring and improving outcomes based on goals.

Common Roles

Project Manager

Operations Manager

Business Manager

Strategic Planner

Systems Engineering

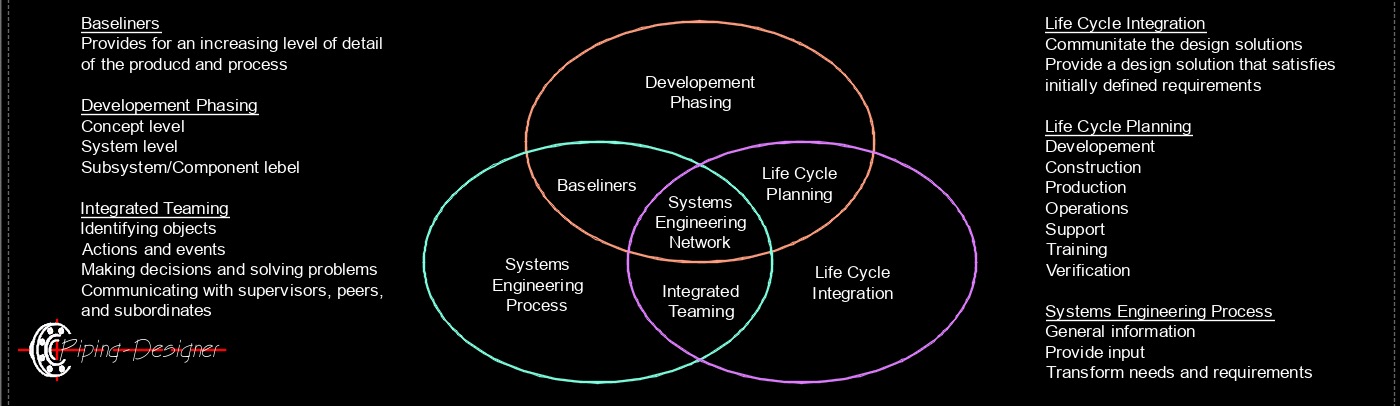

Systems is an interdisciplinary approach that focuses on designing, integrating, and managing complex systems throughout their lifecycle. It deals with technical and systemic challenges to ensure the system functions as intended.

Key Points about Systems

System Design - Creating and integrating components to meet requirements.

Requirements Engineering - Defining and managing system requirements.

Lifecycle Management - Managing a system from conception to disposal.

Interdisciplinary Integration - Bridging various engineering disciplines (mechanical, electrical, software).

Risk Management - Identifying and mitigating risks in system development and operation.

Common Roles

Systems Engineer

Integration Engineer

Requirements Analyst

Lifecycle Engineer

Intersection

In fields like project management, systems engineering management, or operations, both disciplines often collaborate. Understanding both fields can enhance effectiveness in managing and delivering complex projects or systems.

Managers may oversee the development of systems, relying on Systems Engineers for technical insights.

Systems Engineers might require managerial skills to coordinate interdisciplinary teams and communicate with stakeholders.