Hanging Pipe Support

A hanging pipe support, also called pipe hanger, is a device or mechanism used to suspend and support pipes from overhead structures, walls, or other surfaces. These supports are crucial in various industries, including construction, plumbing, HVAC, and industrial processing, to ensure that pipes are held securely in place and properly aligned.

- See Article - Pipe Support Dont's

Key Points about Hanging Pipe Supports

There are various types of hanging pipe supports, each designed for specific applications and load bearing capacities.

Weight Distribution - Pipes can be heavy, especially when filled with fluids. Hanging pipe supports distribute the weight of the pipe and its contents to prevent excessive stress on the pipe itself and the surrounding structures.

Vibration and Movement - Properly designed hanging supports can dampen vibrations and movement caused by the flow of fluids, temperature changes, and other external factors. This helps to reduce the risk of damage to the pipe and other connected components.

Thermal Expansion and Contraction - Pipes can expand and contract due to temperature changes. Hanging supports should allow for limited movement to accommodate thermal expansion and contraction without causing damage.

Alignment - Accurate alignment of pipes is essential for efficient flow and to prevent leaks or other issues. Hanging pipe supports help maintain proper alignment even in situations where pipes might shift due to various factors.

Hanging Pipe Support Types

Proper selection and installation of hanging pipe supports are critical to the integrity and longevity of piping systems. Engineers and designers consider factors such as pipe material, size, weight, operating conditions, and structural requirements when choosing the appropriate type of support for a specific application.

Pipe Clamps - These are simple supports that wrap around the pipe and attach to a structure using bolts, U-bolts, or threaded rods. They come in different designs to accommodate various pipe sizes and materials.

Clevis Hangers - Clevis hangers consist of a yoke-shaped bracket (clevis) and a threaded rod. The clevis holds the pipe, while the threaded rod is attached to a structure.

Roller Supports - These supports allow pipes to expand and contract by using rollers that the pipe rests on. They are suitable for long pipelines that experience significant thermal movement.

Constant Supports - Constant supports use spring mechanisms to provide a consistent lifting force regardless of the pipe's vertical position. They are often used in long pipe runs.

Variable Spring Hangers - These hangers use springs to provide varying levels of support based on the pipe's position. They are effective for managing both thermal expansion and variable loads.

Hanging Support

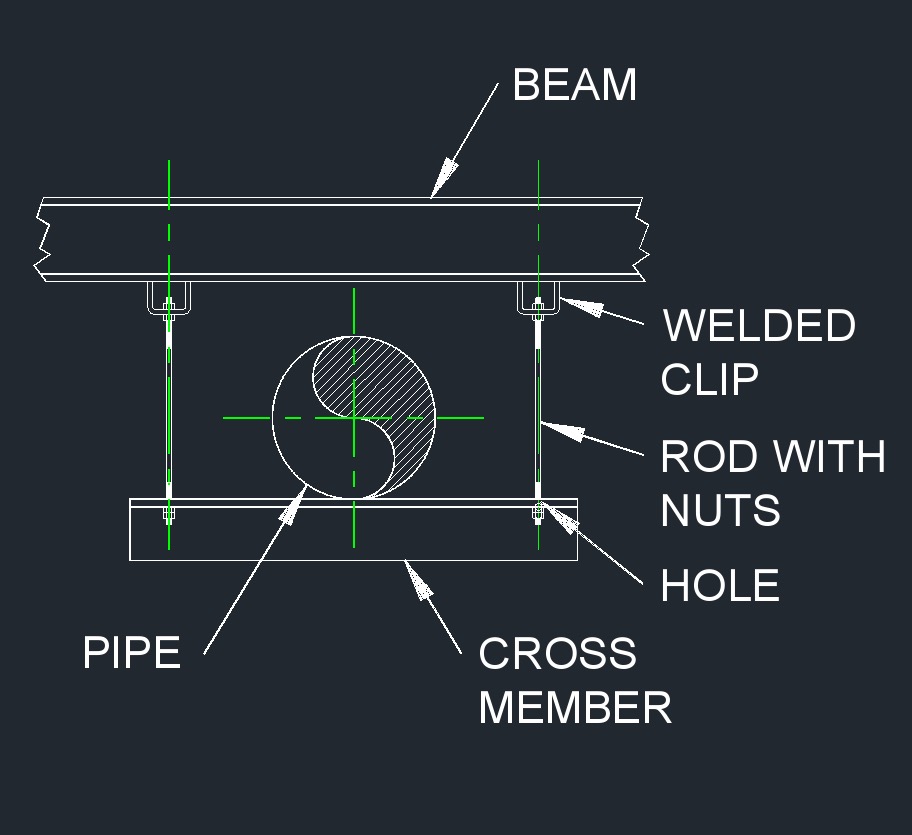

Angle Iron & Rod Support

Angle Iron & Rod Support

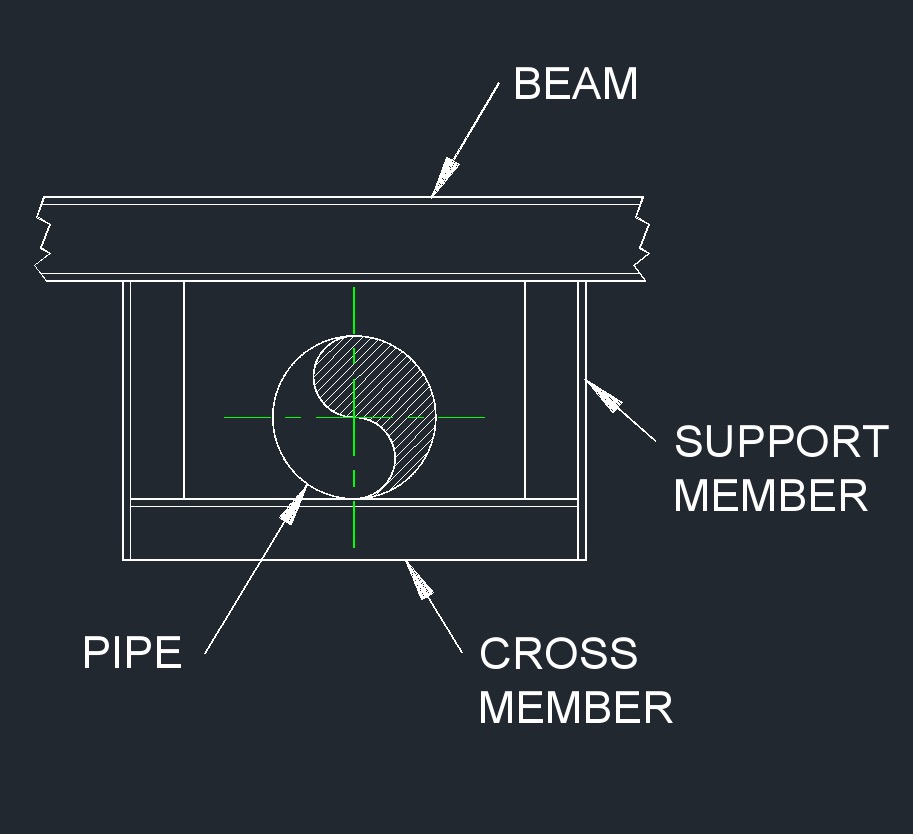

Angle Iron Support

Angle Iron Support