Cavitation

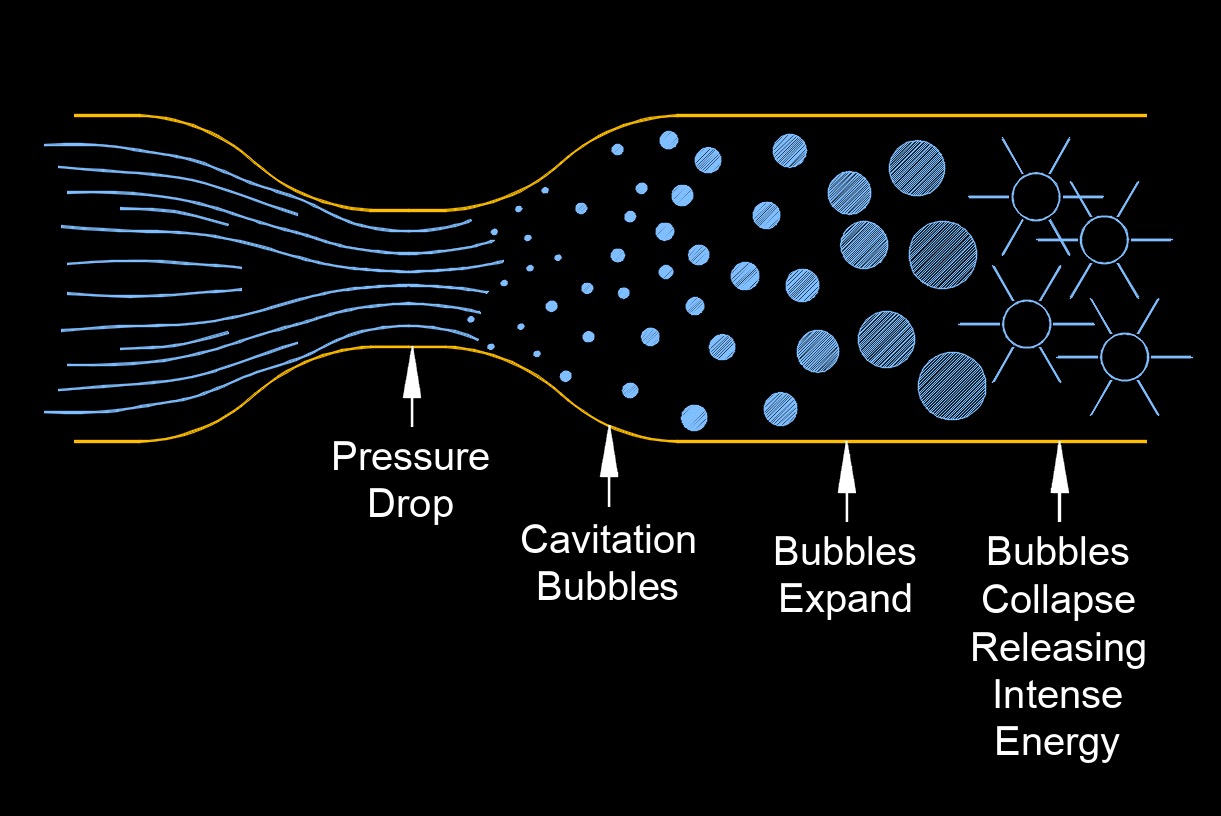

Cavitation, abbreviated as \(K\), is used in fluid dynamics where rapid changes in pressure within a liquid lead to the formation and collapse of vapor bubbles. This process occurs when the pressure in a liquid drops below its vapor pressure, causing the formation of small vapor-filled cavities or bubbles. When these bubbles move to regions of higher pressure, they collapse, creating shock waves and intense localized forces.

Cavitation, abbreviated as \(K\), is used in fluid dynamics where rapid changes in pressure within a liquid lead to the formation and collapse of vapor bubbles. This process occurs when the pressure in a liquid drops below its vapor pressure, causing the formation of small vapor-filled cavities or bubbles. When these bubbles move to regions of higher pressure, they collapse, creating shock waves and intense localized forces.

Localized cavities of vapor form on the low pressure side of the pump (suction) and collapse on themselves as energy is added to the fluid. Cavitation can occur across valves or pumps. As liquid travels from suction nozzle to impeller eye, it will experience pressure losses caused by friction, acceleration, and shock at blade entry. If the pressure of the fluid goes below its vapor pressure, localized vapor bubbles will form in the impeller eye, travel through the impeller, and upon reaching a high pressure region, collapse.

Key Points about Cavitation

A cavitation bubble is a vapor-filled void or cavity that forms in a liquid, typically as a result of changes in pressure. This occurs when the local pressure in a liquid drops below its vapor pressure, causing the liquid to vaporize and form bubbles. Cavitation bubbles play a significant role in various engineering, scientific, and medical applications.

Formation of Bubbles - Cavitation begins with the formation of vapor bubbles in a liquid. This can happen when the local pressure drops due to factors such as high fluid velocity, changes in fluid properties, or obstacles in the flow.Bubble Collapse - Once formed, these bubbles are carried to regions of higher pressure. When they reach an area of higher pressure, the bubbles collapse rapidly. The collapse can generate very high temperatures and pressures locally.

Effects of Cavitation

- Erosion - The collapse of bubbles near solid surfaces can lead to erosion. The repeated implosion of bubbles near a material can cause damage over time.

- Noise - Cavitation can produce noise, often described as a characteristic "clicking" or "hammering" sound.

- Vibration - The collapse of bubbles generates shock waves and vibrations, which can impact equipment and structures.

- Industrial Pumps - Cavitation is a concern in pumps and propellers, where it can lead to decreased efficiency and equipment damage.

- Sonoluminescence - In certain conditions, cavitation can lead to the emission of light, a phenomenon known as sonoluminescence.

- Medical Applications - Cavitation is used in medical procedures such as ultrasonic cleaning and medical imaging.

Preventing Cavitation - To mitigate the effects of cavitation, engineers may design systems with features such as properly shaped propellers, anti-cavitation devices, and materials resistant to erosion.

Key Points about and Aspects of Cavitation Bubbles

Sizes - Cavitation bubbles can vary in size from microscopic to macroscopic, depending on the conditions and the specific application. Microbubbles are often involved in biomedical applications and certain industrial processes, while larger cavitation bubbles can occur in hydraulic systems or marine propellers.

Motion - Cavitation bubbles are not stationary; they can move within the liquid. Bubbles tend to be carried by the fluid flow to regions of higher or lower pressure, where they either grow in size or collapse, depending on the local pressure conditions.

Collapse - The collapse of cavitation bubbles is a critical aspect of the phenomenon. When a bubble moves to a region of higher pressure, it rapidly collapses. The collapse generates shock waves, high temperatures, and intense localized pressures. This collapse phase is often referred to as cavitation implosion.

Sonoluminescence - Under certain conditions, the collapse of cavitation bubbles can result in the emission of light, a phenomenon known as sonoluminescence. This occurs when the bubble collapses so rapidly that it reaches extremely high temperatures for a very short duration.

Applications - Cavitation bubbles have both positive and negative implications in various applications. In positive scenarios, controlled cavitation is used in medical procedures (ultrasound imaging and therapy), industrial cleaning processes, and even in some chemical reactions. On the negative side, uncontrolled or excessive cavitation can lead to damage in machinery and components, as discussed earlier.

Control and Management - Engineers and scientists employ various techniques to control and manage cavitation bubbles in different applications. This may involve designing equipment to minimize cavitation, introducing materials resistant to cavitation damage, or incorporating features like bubble traps.

The Collapse of Bubbles Near Solid Surfaces Can Lead to Several Types of Damage

Cavitation damage is the detrimental effects caused by the process of cavitation on surfaces or materials. This damage occurs when vapor bubbles form and collapse in a liquid, generating intense local forces and pressures. Understanding cavitation and its potential for damage is crucial in designing and maintaining systems that involve fluid flow. Engineers strive to minimize cavitation effects through careful design considerations and the use of appropriate materials and technologies.

Erosion - One of the primary forms of cavitation damage is erosion. As vapor bubbles collapse near a material surface, they generate high-speed liquid jets and shock waves. These can cause the removal of material from the surface, leading to erosion. This erosion can be particularly problematic in components such as pumps, valves, and propellers.Pitting - Cavitation-induced pitting is characterized by the formation of small pits or craters on the surface of a material. The repeated collapse of vapor bubbles creates localized pressure waves that impact the material surface, leading to the formation of these pits.

Cracking - In some cases, the intense shock waves generated during cavitation can lead to the development of cracks in the material. This is especially true in materials that are brittle or susceptible to fatigue.

Material Weakening - The cyclic nature of cavitation, with the formation and collapse of bubbles occurring repeatedly, can lead to material fatigue and a gradual weakening of the material over time. This can compromise the structural integrity of components.

Reduced Performance - In systems such as pumps and propellers, cavitation can lead to a decrease in performance. As erosion and pitting occur, the efficiency of the equipment may be reduced, ultimately impacting its overall effectiveness.

Noise and Vibration - Cavitation induced damage is often accompanied by increased noise and vibration. The collapse of bubbles generates shock waves and acoustic energy, contributing to the overall wear and tear of the system.

Prevention and Mitigation - Engineers employ various strategies to prevent or mitigate cavitation damage. This may involve optimizing the design of components, selecting materials resistant to cavitation, and incorporating features such as cavitation-resistant coatings or anti-cavitation devices.

Cavitation in a Pump

Cavitation in a pump occurs when the local pressure of the liquid being pumped drops below its vapor pressure, leading to the formation and subsequent collapse of vapor bubbles. This can have detrimental effects on the pump and its performance.

How Cavitation Typically Occurs in a Pump and its Consequences

Addressing cavitation in pumps is essential for ensuring the longevity and efficient operation of pumping systems. Regular maintenance, monitoring of performance parameters, and proper design practices contribute to effective cavitation control.

Formation of Vapor Bubbles - As the pump impeller rotates, it generates a flow of liquid. In certain conditions, such as high flow velocities or changes in fluid properties, the local pressure at the impeller blades may drop below the vapor pressure of the liquid. This causes the liquid to vaporize, forming cavitation bubbles.Bubble Movement - The cavitation bubbles are carried by the flow of liquid to regions of higher pressure, typically as they move away from the impeller. When the bubbles reach higher-pressure zones, they collapse.

Bubble Collapse - The collapse of cavitation bubbles is associated with the release of energy in the form of shock waves and high-speed liquid jets. This can lead to erosion, pitting, and damage to the pump components, particularly the impeller blades and nearby surfaces.

Noise and Vibration - Cavitation in a pump is often accompanied by distinct noise, which is characterized by a "hammering" or "rattling" sound. The collapse of bubbles also generates vibrations that can further contribute to wear and tear.

Impact on Pump Efficiency - Cavitation can significantly reduce the efficiency of a pump. As the impeller blades are eroded and pitted, the pump's ability to generate the necessary flow and pressure diminishes. This can result in decreased performance and increased energy consumption.

Prevention and Control - Engineers employ various strategies to prevent or mitigate cavitation in pumps.

- Proper Pump Design - Ensuring that the pump is designed to handle the specific flow rates and pressure conditions is crucial.

- NPSH (Net Positive Suction Head) - Maintaining an adequate NPSH is critical to prevent cavitation. NPSH is a measure of the pressure head available at the pump's suction to prevent the formation of vapor bubbles.

- Materials and Coatings - Using materials and coatings that are resistant to cavitation damage can extend the life of pump components.

Key Effects of Cavitation in a Pump

Cavitation in a pump can have various detrimental effects on its performance and components. To prevent or mitigate these effects, engineers and operators must carefully design pump systems, monitor operating conditions, and implement strategies such as maintaining adequate Net Positive Suction Head (NPSH), choosing materials resistant to cavitation, and utilizing anti-cavitation devices when necessary. Regular maintenance and performance monitoring are crucial for identifying and addressing cavitation related issues promptly

Erosion and Pitting - The collapse of cavitation bubbles generates intense shock waves and high-speed liquid jets. As these bubbles collapse near the surfaces of pump components, particularly the impeller blades, they can cause erosion and pitting. This leads to the gradual removal of material from the surface, compromising the integrity of the components.

Reduced Pump Efficiency - Cavitation can significantly reduce the efficiency of a pump. The erosion and pitting of impeller blades diminish the pump's ability to generate the necessary flow and pressure. Reduced efficiency means that the pump has to work harder to achieve the desired output, leading to increased energy consumption.

Noise and Vibration - Cavitation in a pump is often accompanied by distinct noise, characterized by a "hammering" or "rattling" sound. The collapse of bubbles also generates vibrations that can contribute to additional wear and tear on the pump components and surrounding structures.

Increased Operating Costs - The inefficiencies introduced by cavitation can result in higher operating costs. Pumps operating under cavitation conditions may require more frequent maintenance and repairs, leading to increased downtime and associated costs.

Cavitation Induced Damage - In addition to erosion and pitting, cavitation can lead to other forms of damage, including fatigue cracks in pump components. The cyclic nature of cavitation, with the formation and collapse of bubbles occurring repeatedly, can contribute to material fatigue and the development of cracks.

Altered Flow Patterns - Cavitation can alter the flow patterns within the pump. As vapor bubbles collapse and create turbulence, the normal flow characteristics may be disrupted. This can further contribute to inefficiencies and impact the pump's overall performance.

Temperature Rise - The collapse of cavitation bubbles is associated with a rapid increase in temperature in the surrounding fluid. While this temperature rise is localized and short lived, it can contribute to accelerated wear and may have implications for the properties of the pumped fluid.

Cavitation Related Vibrations - Cavitation induced vibrations can affect not only the pump components but also the entire system. Excessive vibrations can lead to mechanical problems, misalignments, and potential damage to support structures.

Low NPSA (Net Positive Suction Head)

When the Net Positive Suction Head (NPSHa) is less than the required suction head. When the NPSHr exceeds the NPSHa, cavitation will occur. There are several solutions for this.

- Decrease the vapor pressure by lowering the fluid's temperature.

- Increase the amount of NPSHa by increasing level or raising the pressure in the tank or vessel.

- Minimize pressure drop from the tank, vessel or equipment to the suction of the pump.

- Unnecessary fittings, long distances and piping conditions should be examined.

- Decrease the NPSHr by changing the characteristics of the pump.

Gas in the Lines

If there is entrained gas or bubbles in the line, vapor bubbles can collapse on themselves as the pressure rises and cause cavitation. This can be solved by adapting the process to minimize the amount of entrained gas.

Effects in a Pump

- Noise, excessive vibration, mechanical damage to the impeller. Cavitation sounds like gravel or marbles running through the pipe or the pump.

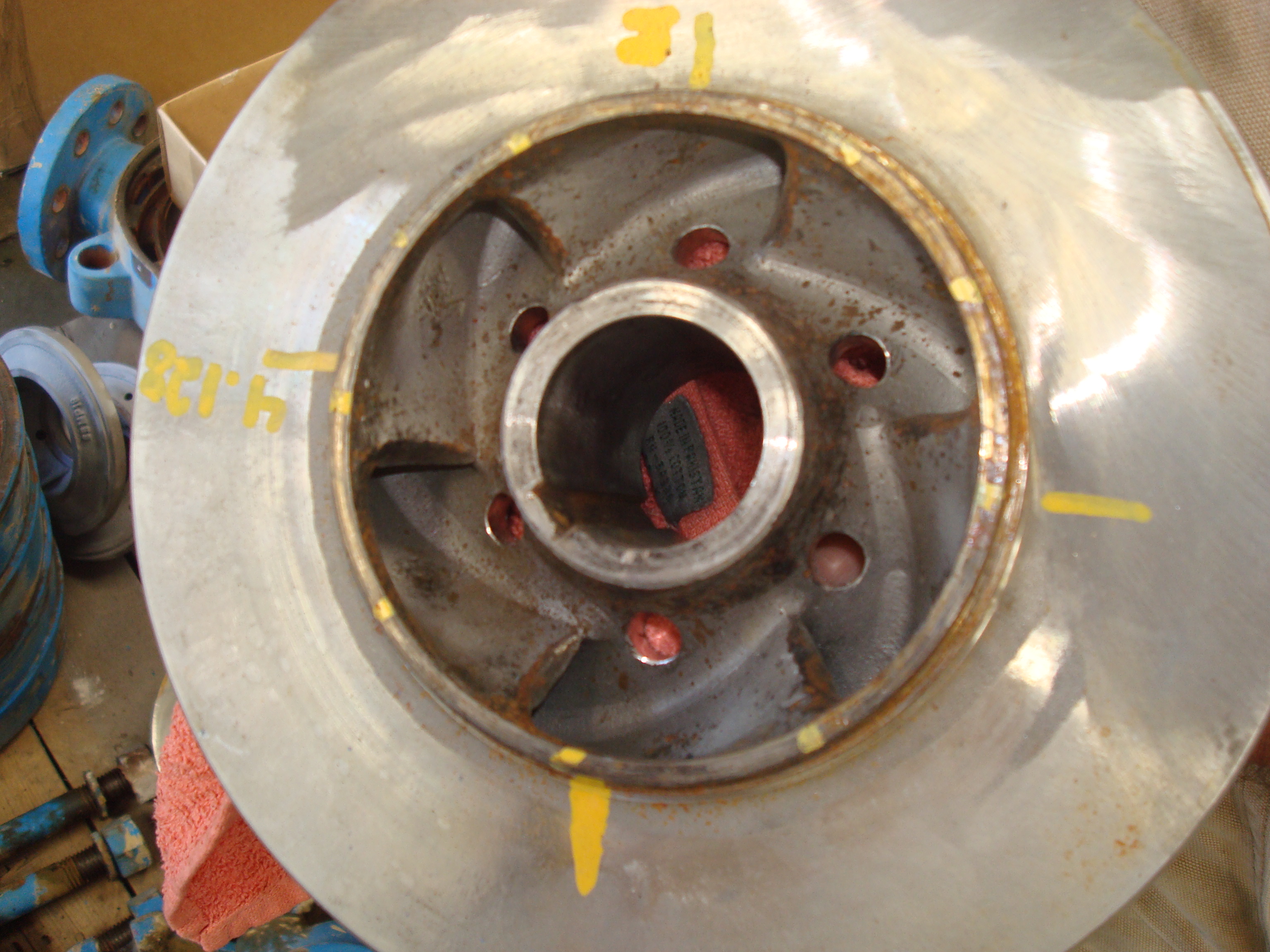

- The sound is actually tiny air bubbles forming and imploding on themselves rapidly. The implosion of the air bubbles collapses with so much force that it takes a bit of the component's material while its up against a pump wall or on the seat of a valve. An example of cavitation corrosion is shown below. The pump impeller (and casing) both exhibit signs of cavitation. Note that it looks like it was struck with a ball peen hammer or small ball bearings at the rusted portion of the photos.

- Cavitation also causes increased forces on the components of the pump which can cause bearing failure or mechanical seal failure. Once the bearing fails, catastrophic shaft failure is close behind.

- Decrease in capacity of the pump. Because vapor bubbles take more volume than liquid, increased bubbles will displace the liquid being pumped and cause the pump to reduce its capacity.

- Resultant head pressure and pump efficiency drop.

Examples of Cavitation

Cavitation Effects on a Pump Impeller