Pump

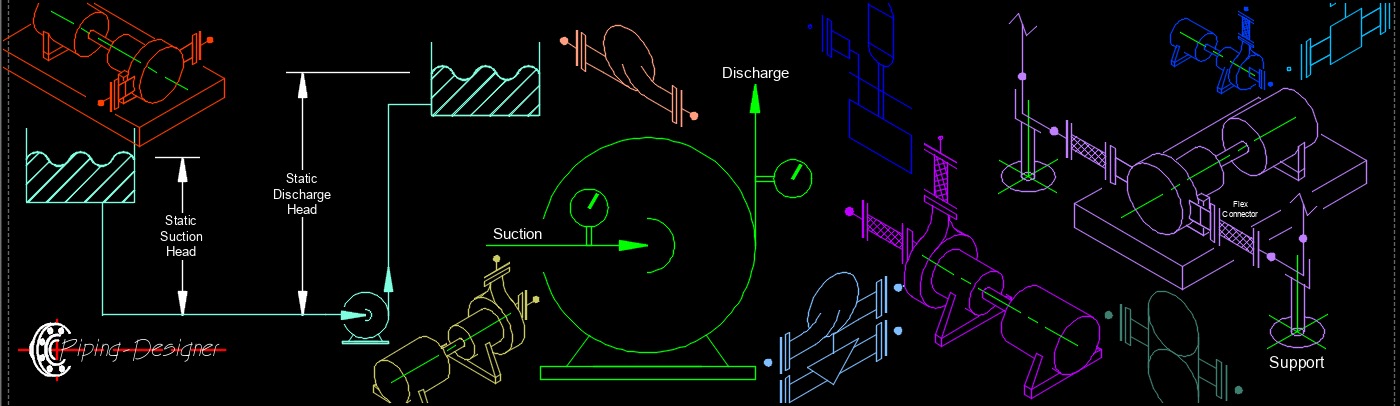

Pump, Motor, Rotating Equipment Pumps are mechanical devices that are used to move fluids (liquids or gases) from one location to another. They come in many different types and sizes, depending on the specific application and requirements and work by creating a pressure difference that forces the fluid to flow in a specific direction. Pumps can be powered by various sources, such as electric motors, internal combustion engines, or steam turbines. They can also be designed for different levels of pressure, flow rate, and viscosity, depending on the specific application.

Pumps are mechanical devices that are used to move fluids (liquids or gases) from one location to another. They come in many different types and sizes, depending on the specific application and requirements and work by creating a pressure difference that forces the fluid to flow in a specific direction. Pumps can be powered by various sources, such as electric motors, internal combustion engines, or steam turbines. They can also be designed for different levels of pressure, flow rate, and viscosity, depending on the specific application.

| Engineering |

| Mechanical Engineering |

The specific function of a pump depends on the type and design of the pump, as well as the specific application. For example, centrifugal pumps are commonly used in industrial applications and HVAC systems to circulate water or other fluids, while positive displacement pumps are often used in chemical processing or oil and gas production to move viscous or abrasive fluids.

Pumps play a critical role in many industries and applications, such as in water and wastewater treatment, oil and gas production, and food and beverage processing. Regardless of the type or application, pumps are essential for many industrial processes and infrastructure systems. They must be designed, installed, and maintained properly to ensure their safe and efficient operation.

- See Article - Pump Glossary

Pump Types

Gas and Vapor Movers

- Kinetically Driven Pump - Energy is continuously added to increase the fluid velocities within the pump to values greater than those occurring at the discharge, so subsequent velocity reduction within or beyond the pump produces a pressure increase.

- Rotary

- Axial Pump

- Centrifugal Pump

- Mixed-flow Pump

- Jet Pump

- Submersible Pump

- Axial Pump

- Nonrotary

- Ejector or Recompressor

- Rotary

- Positive Displacement Pump - Fluid moves by trapping a fixed amount and displacing that trapped volume into the discharge pipe. Some pumps use an expanding cavity on the suction side and a decreasing cavity on the discharge side. The volume of liquid is constant for each operational cycle.

- Rotary

- Liquid Ring Vacuum Pump

- Lobe Compressor and Vacuum Pump

- Vane Compressor and Vacuum Pump

- Screw Compressor

- Nonrotary

- Reciprocating Compressor - Compressors are mechanical devices used to intentionally increase the pressure of a air. This compressor consist of a piston driven by a crankshaft enclosed within a cylinder. The typical reciprocating air compressor is also comprised of suction and discharge valves. These type of compressors operate by drawing fluid into a fixed-volume chamber by a mechanical component which physically displaces the air.

- Reciprocating Compressor - Compressors are mechanical devices used to intentionally increase the pressure of a air. This compressor consist of a piston driven by a crankshaft enclosed within a cylinder. The typical reciprocating air compressor is also comprised of suction and discharge valves. These type of compressors operate by drawing fluid into a fixed-volume chamber by a mechanical component which physically displaces the air.

- Rotary

Liquid Movers

- Kinetically Driven Pump - Energy is continuously added to increase the fluid velocities within the pump to values greater than those occurring at the discharge, so subsequent velocity reduction within or beyond the pump produces a pressure increase.

- Rotary

- Axial Pump - A pump where a case is split parallel to pump shaft. These pumps are used in high flow and low head applications. They are suitable for both low and high pressure, and are specially designed to handle severe pumping conditions.

- Centrifugal Pump - A very basic piece of equipment in the oil field. This type of hydraulic pump is used to transform the mechanical energy of a propeller or turbine into kinetic energy or pressure to an uncompressible fluid. The centrifugal pump thus converts the energy with which it is worked, in this case mechanical, into hydraulic energy.

- Mixed-flow Pump - Since the shape of the impeller of the mixed flow pump is between the centrifugal pump impeller and the axial flow pump impeller, the working principle of the mixed flow pump has both centrifugal force and lift. The impeller sits within the pipe and turns, but the turning mechanism is essentially diagonal, using centrifugal force to move the water along while accelerating it further with the push from the axial direction of the impeller. This creates enough force to generate high rates of flow.

- Nonrotary

- Jet Eductor - This pump works by pumping pressurized fluid through a nozzle in the eductor, creating a partial vacuum on the suction side of the eductor. Liquid or vapor is then pulled up into suction tube that is attached to the suction side of each eductor. The recovered liquid or vapor is carried along by the pressurized fluid, and the mixture is discharged through the eductor to discharge piping.

- Jet Eductor - This pump works by pumping pressurized fluid through a nozzle in the eductor, creating a partial vacuum on the suction side of the eductor. Liquid or vapor is then pulled up into suction tube that is attached to the suction side of each eductor. The recovered liquid or vapor is carried along by the pressurized fluid, and the mixture is discharged through the eductor to discharge piping.

- Rotary

- Positive Displacement Pump - Fluid moves by trapping a fixed amount and displacing that trapped volume into the discharge pipe. Some pumps use an expanding cavity on the suction side and a decreasing cavity on the discharge side. The volume of liquid is constant for each operational cycle.

- Rotary

- Gear Pump - This pump uses the meshing of gears to pump fluid by displacement. Due to their simplicity, versatility and their high reliability they are one of the most common types of pumps for hydraulic fluid power applications. External gear pumps include two external gears (inside the pump housing), one being a drive gear and the other being an idler gear. Internal gear pumps include one external gear and one internal gear located inside the external gear (both inside the pump housing).

- Peristaltic Pump - They are typically used for pumping caustic, abrasive, or sensitive fluids and are ideal for long runs with continuous flow. This pump can be used to deliver a precisely measured volume, specific load of liquid material. Variable speed peristaltic pumps are used for continuous pumping at a variety of motor speeds. The flexible tube is compressed between the pump housing and the rollers. The rollers are housed within the pump head. The compressed portion of the tube forces the liquid material through the tube, which delivers the desired dose of fluid.

- Progressive Cavity Pump - It features a suction inlet which feeds into an elongated casing. Within this casing sits a helical worm rotor and stator assembly. The rotor helix is shaped off-set to the stator creating cavity spaces in the assembly which are formed by temporary seals as the rotor contacts the surface of the stator. As the rotor begins to move in an eccentric fashion, the cavities form, draw in product and are progressed along the assembly and the product is expelled through the discharge port.

- Screw Pump - These pumps are rotary, positive displacement pumps that use one or more screws to transfer fluids along an axis.

- Single Screw Pump - Has a single pumping element (screw) that rotates within a stationary. The individual turns of the screw seal a set volume of fluid by direct contact, with the stator. The stator has a shape that corresponds to the outside surface of the screw. The interference fit between the screw or pumping element and the flexible stator create a unique pump design that can handle a variety of fluid characteristics, including high levels of solids and variable viscosities.

- Two Screw Pump - This pump has two shafts. However, a two screw pump can also be considered a four screw pump if it is a double suction design (two opposing sets of screws pumping towards the discharge). The pumping element of a two screw pump consists of two intermeshing screws rotating within a stationary housing that is shaped like a figure eight.

- Vane Pump - This pump delivers a constant flow rate under different pressure conditions because it pressurizes the fluid due to the impact of the vanes. It has a different number of vanes installed on a rotor that moves in the cavity. Sometimes, these vanes can be of variable length and tensioned to uphold contact with the wall as the pump derives. The pump also has a pressure relief valve that stops pressure build-up inside the pump that could break the pump.

- Nonrotary

- Reciprocating Pump

- Diaphragm Pump - It is a pump that uses a combination of the reciprocating action of a diaphragm and a series of check valves to pump a fluid. The membrane is mechanically pushed and pulled in and out of a pumping chamber. When the diaphragm is collapsed all of the air is forced out of the diaphragm chamber. When the diaphragm is extended the slurry, or whatever is being pumped, is sucked into the diaphragm chamber through the intake line. The slurry will be discharged out of the discharge line.

- Piston Pump - It is one of the oldest styles of pumps that is still in use. Its design is very simple. A piston moves in and out of a cylinder. This type of pump is often used for high pressure applications and hydraulic systems. It is capable of pumping high viscosity fluids and fluids which contain solids.

- Plunger Pump - Used at wastewater treatment plants, car washes, food processing plants, and in the oil and gas industry to regulate the flow of fluids. It consists of two valves mounted in a pumping chamber that controls the action of a plunger into a suction force or discharge force. The design of the machine allows solids to flow freely without clogging the system.

- Reciprocating Pump

- Rotary