Welding Heat Input Required

Welding Heat Input Required Formula |

||

|

\( H \;=\; \dfrac{ V \cdot I \cdot 60 }{ 1000 \cdot s } \cdot k \) (Welding Heat Input Required) \( V \;=\; \dfrac{ H \cdot 1000 \cdot s }{ k \cdot I \cdot 60 } \) \( I \;=\; \dfrac{ H \cdot 1000 \cdot s }{ k \cdot V \cdot 60 } \) \( s \;=\; \dfrac{ V \cdot I \cdot 60 \cdot k }{ H \cdot 1000 } \) \( k \;=\; \dfrac{ H \cdot 1000 \cdot s }{ V \cdot I \cdot 60 } \) |

||

| Symbol | English | Metric |

| \( H_i \) = Welding Heat Input Required | \(kJ \;/\; in \) | \(kJ \;/\; mm \) |

| \( V \) = Arc Voltage | \( V \) | \( V \) |

| \( I \) = Welding Current | \( A \) | \( A \) |

| \( s \) = Travel Speed | \(in\;/\;min\) | \(mm\;/\;min\) |

| \( k \) = Thermal Efficiency Factor of the Welding Process | \(dimensionless\) | \(dimensionless\) |

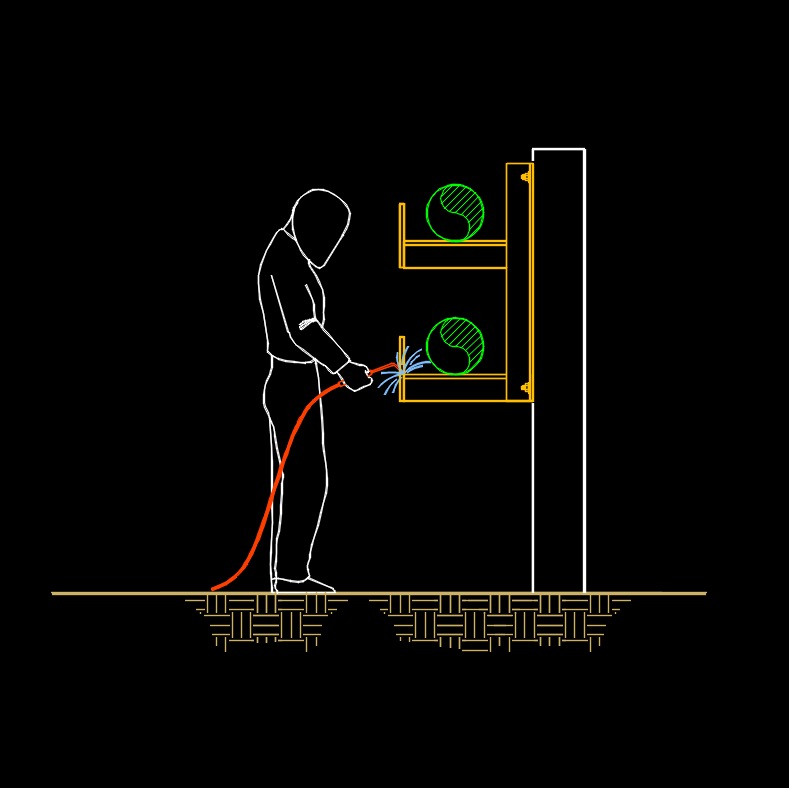

Welding heat input required, abbreviated as \(H_i \) and \(Q\), is the amount of energy transferred into the material being welded during the welding process. It is an important parameter in welding because it can affect the quality, strength, and properties of the welded joint. The heat input required for welding depends on various factors, including the type of material being welded, the welding process used, the welding parameters, and the desired properties of the welded joint.

Welding heat input required, abbreviated as \(H_i \) and \(Q\), is the amount of energy transferred into the material being welded during the welding process. It is an important parameter in welding because it can affect the quality, strength, and properties of the welded joint. The heat input required for welding depends on various factors, including the type of material being welded, the welding process used, the welding parameters, and the desired properties of the welded joint.

Breakdown of the Components

Voltage - The electrical potential difference across the welding arc, usually measured in volts. The voltage determines the electrical energy supplied to the arc.

Current - The electrical current passing through the welding arc, typically measured in amperes. The current determines the rate of flow of electricity, which also affects the energy input.

Welding Speed - The speed at which the welding electrode or torch moves along the joint. Faster welding speeds reduce the heat input, while slower speeds increase it.

The required heat input for a particular welding application can vary widely based on the materials and specifications. In some cases, a lower heat input may be preferred to minimize the risk of distortion, heat affected zone (HAZ) size, or metallurgical changes in the base metal. In other cases, a higher heat input may be necessary to ensure good fusion and penetration, especially when welding thick materials. Welding procedures are often developed and qualified to specify the appropriate heat input range to achieve the desired weld quality and mechanical properties. Welders and welding operators adjust their welding parameters (voltage, current, and travel speed) to control the heat input and meet these requirements.