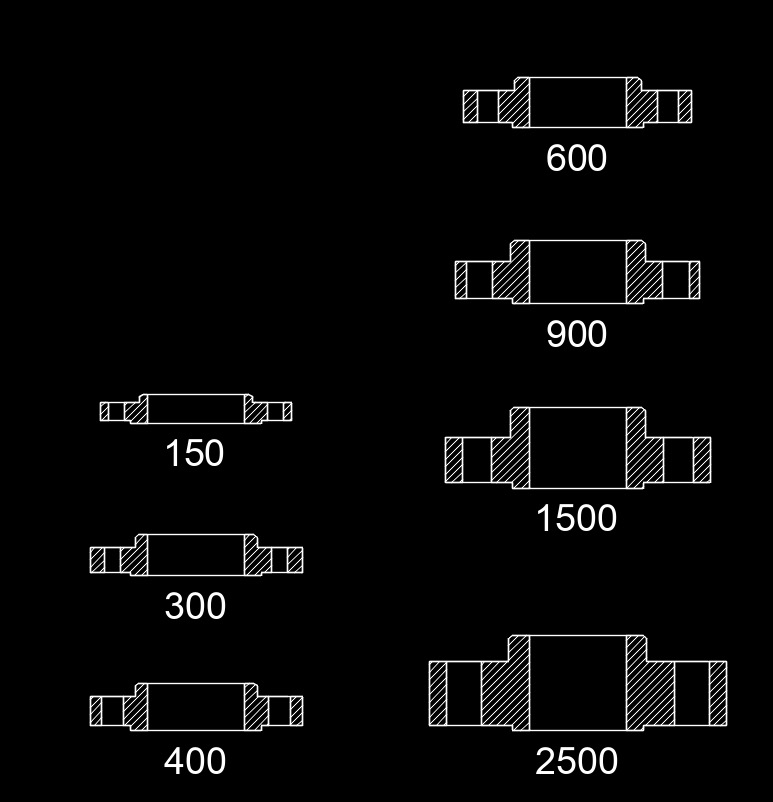

Slip-on Flange

Slip-on Flange Datasheets

| |||

|---|---|---|---|

| Class | Flat Face | Raised Face | Ring Type Joint |

| ANSI 150 | SO Flange ANSI 150 FF (in) | SO Flange ANSI 150 RF (in) | SO Flange ANSI 150 RTJ (in) |

| ANSI 300 | SO Flange ANSI 300 FF (in) | SO Flange ANSI 300 RF (in) | SO Flange ANSI 300 RTJ (in) |

| ANSI 400 | SO Flange ANSI 400 FF (in) | SO Flange ANSI 400 RF (in) | SO Flange ANSI 400 RTJ (in) |

| ANSI 600 | SO Flange ANSI 600 FF (in) | SO Flange ANSI 600 RF (in) | SO Flange ANSI 600 RTJ (in) |

| ANSI 900 | SO Flange ANSI 900 FF (in) | SO Flange ANSI 900 RF (in) | SO Flange ANSI 900 RTJ (in) |

| ANSI 1500 | SO Flange ANSI 1500 FF (in) | SO Flange ANSI 1500 RF (in) | SO Flange ANSI 1500 RTJ (in) |

| ANSI 2500 | SO Flange ANSI 2500 FF (in) | SO Flange ANSI 2500 RF (in) | SO Flange ANSI 2500 RTJ (in) |

Slip-on flanges, abbreviated as SOF, are designed to slip over the outside of pipe, long-tangent elbows, reducers, and swages. The flange has poor resistance to shock and vibration. It is easier to align than a weld neck flange. This flange is ideal for low pressure applications since the strength when under internal pressure is about one third that of a weld neck flange. This flange has a raised face.