Steam Pressure Loss through Piping

Steam Pressure Loss through Piping formula |

||

| \( p_l \;=\; \dfrac{ \mu \cdot l \cdot v \cdot s^2 }{ 24 \cdot d \cdot g \cdot \upsilon }\) | ||

| Symbol | English | Metric |

| \( p_l \) = Steam Pressure Loss | \(lbf\;/\;in^2\) | \(Pa\) |

| \( \mu \) (Greek symbol mu) = Steam Friction Coefficient | \(dimensionless\) | \(dimensionless\) |

| \( l \) = Pipe Length | \( ft \) | \( m \) |

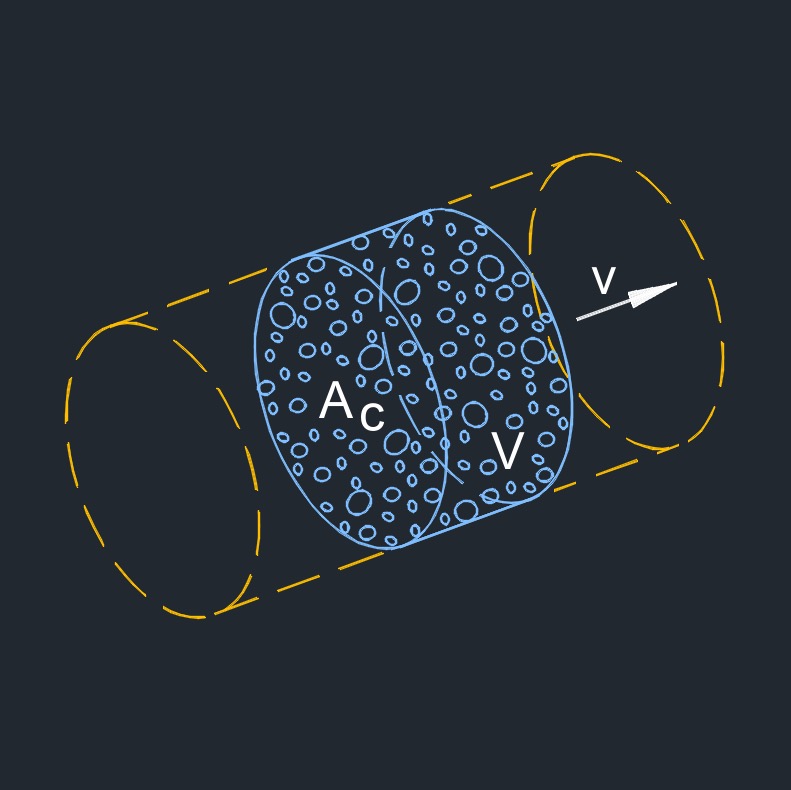

| \( v_s \) = Steam Velocity | \(ft\;/\;sec\) | \(m\;/\;s\) |

| \( d \) = Pipe Inside Diameter | \(in\) | \(mm\) |

| \( g \) = Gravitational Acceleration | \(ft\;/\;sec^2\) | \(m\;/\;s^2\) |

| \( \upsilon \) (Greek symbol upsilon) = Steam Specific Volume | \(ft^3\;/\;lbm\) | \(m^3\;/\;kg\) |

Steam pressure loss through piping is the decrease in steam pressure as it travels through a piping system from its source to its destination. This pressure loss occurs due to various factors such as frictional resistance, changes in elevation, fittings, valves, and other obstructions in the piping. This pressure loss is a critical consideration in the design and operation of steam systems because it affects the efficiency and performance of the system. Excessive pressure loss can result in inadequate steam delivery to end users, increased energy consumption, and potentially system malfunctions.

Steam pressure loss through piping is the decrease in steam pressure as it travels through a piping system from its source to its destination. This pressure loss occurs due to various factors such as frictional resistance, changes in elevation, fittings, valves, and other obstructions in the piping. This pressure loss is a critical consideration in the design and operation of steam systems because it affects the efficiency and performance of the system. Excessive pressure loss can result in inadequate steam delivery to end users, increased energy consumption, and potentially system malfunctions.

Engineers use pressure drop calculations to estimate the pressure loss in steam piping systems. These calculations involve considering factors such as pipe size, length, flow rate, steam properties, and the characteristics of fittings and valves. Various empirical equations and methods are available for estimating pressure drop, depending on the complexity of the system and the level of accuracy required. Proper design, sizing, and layout of piping, along with the selection of appropriate fittings and valves, can help minimize pressure loss and ensure efficient steam distribution within a system. Regular maintenance and monitoring are also essential to detect and address any issues that may cause excessive pressure loss over time.