Beam Design Formulas

Structural beam design refers to the process of determining the appropriate size and shape of beams that will be used in construction to support and distribute loads within a building or structure. Beams are horizontal or inclined structural members that carry vertical loads. The design of structural beams involves several important considerations to ensure the safety, stability, and efficiency of a structure.

|

See Articles

|

See Articles

|

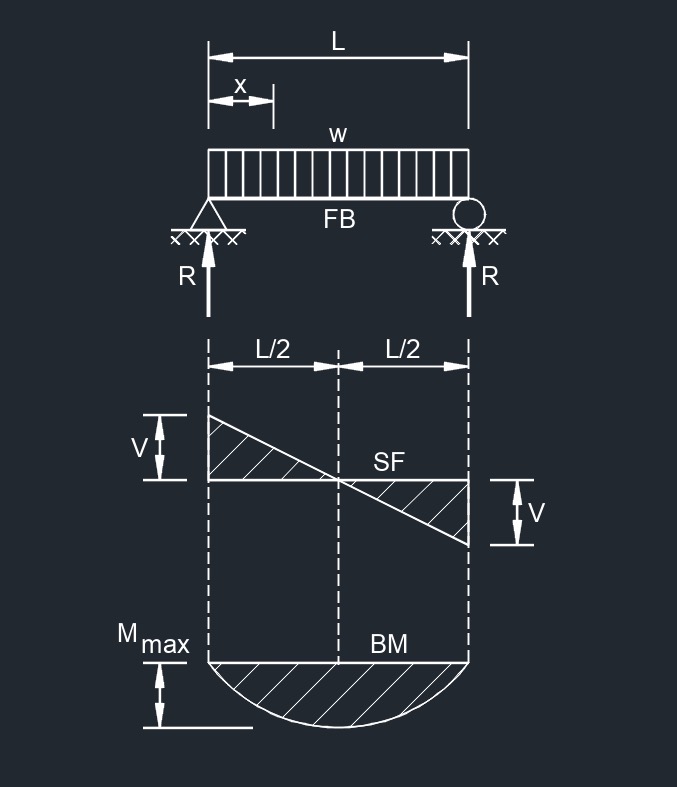

Simple Supported Beam

Uniformly Distributed Load

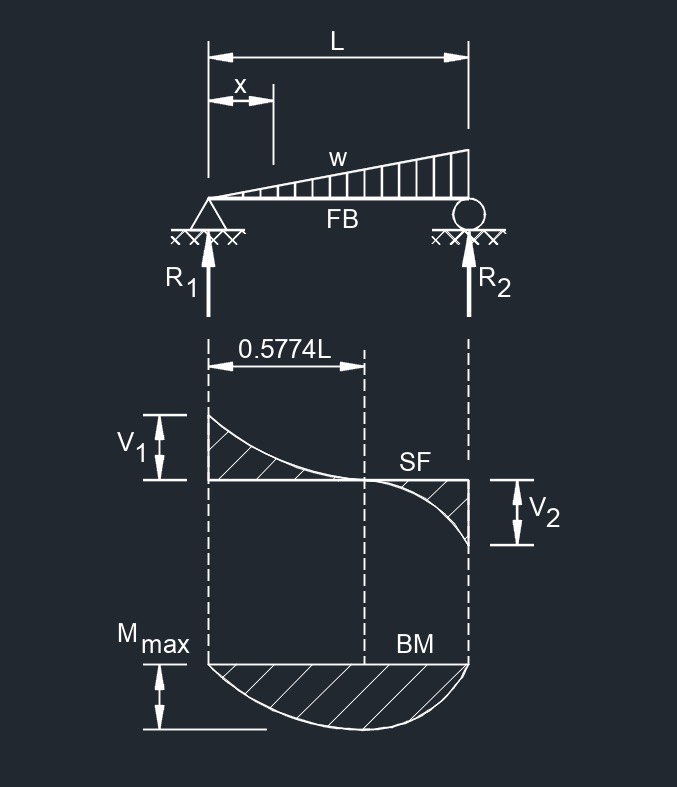

Uniformly Distributed Load  Load Increasing Uniformly to One End

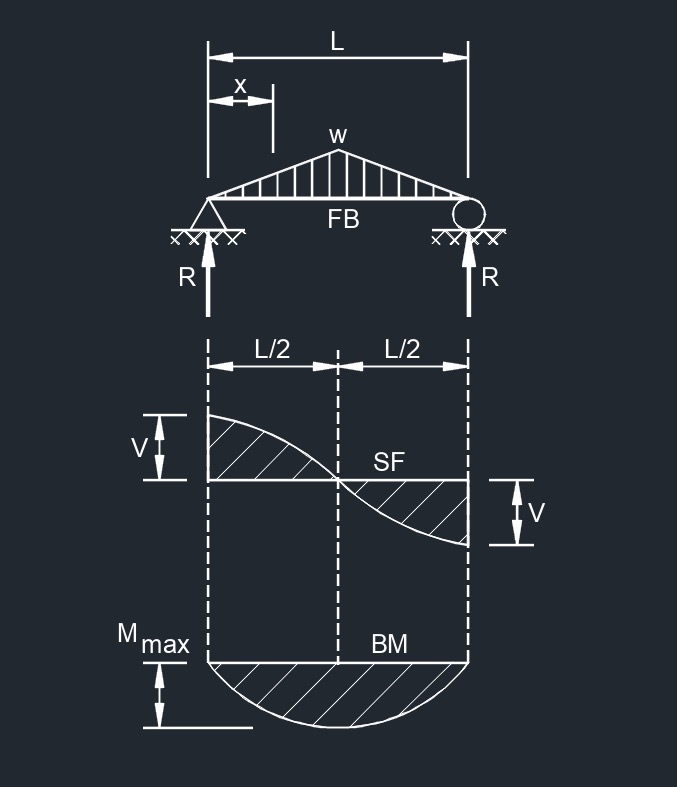

Load Increasing Uniformly to One End  Load Increasing Uniformly to Center

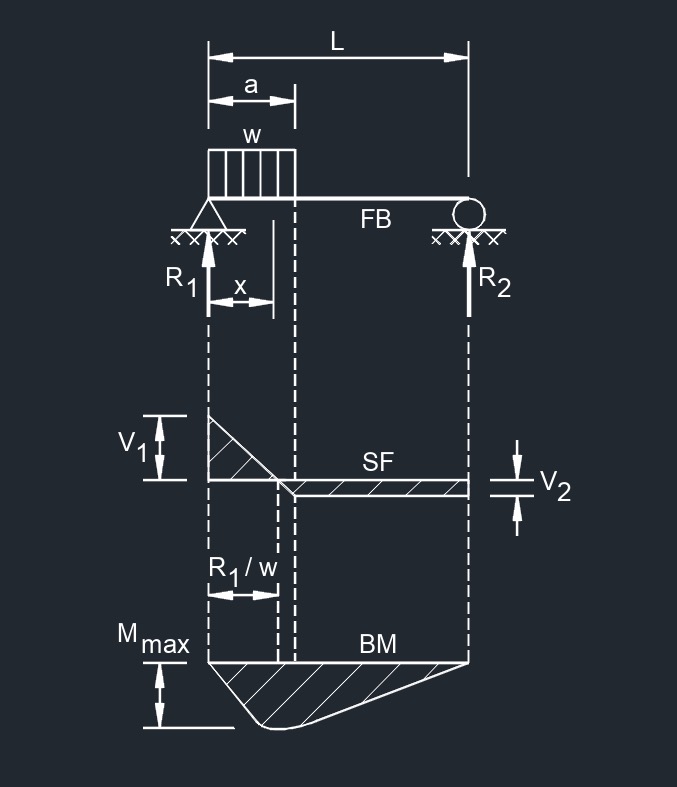

Load Increasing Uniformly to Center  Uniform Load Partially Distributed at One End

Uniform Load Partially Distributed at One End

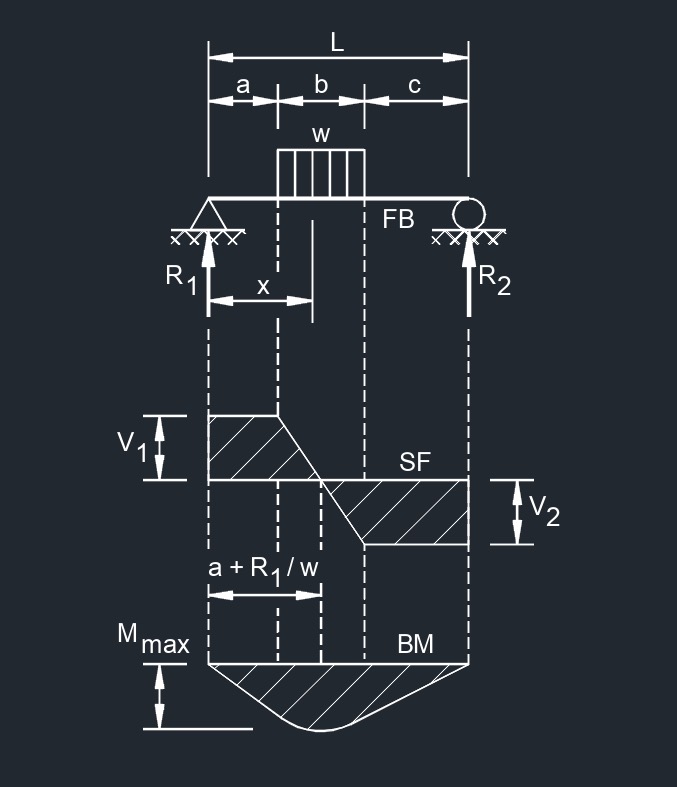

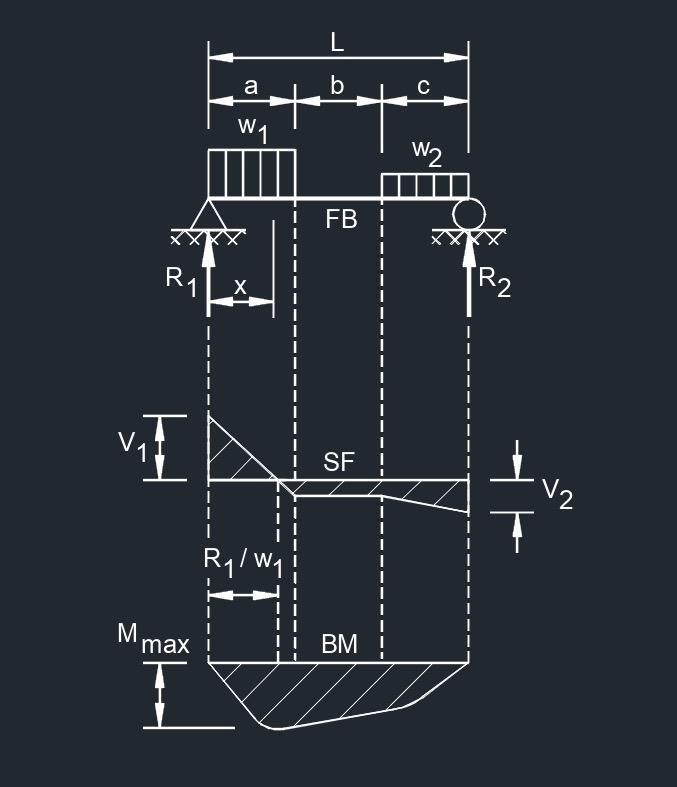

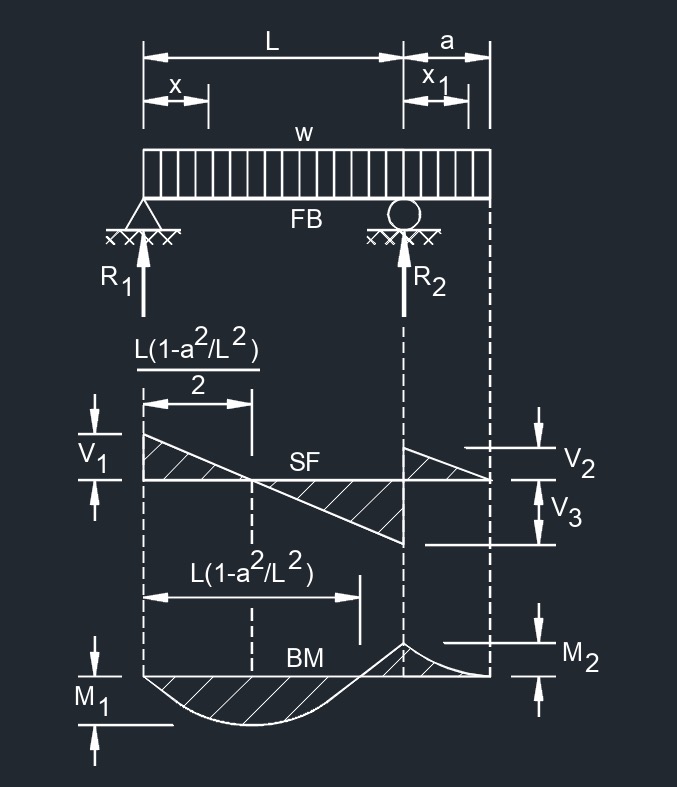

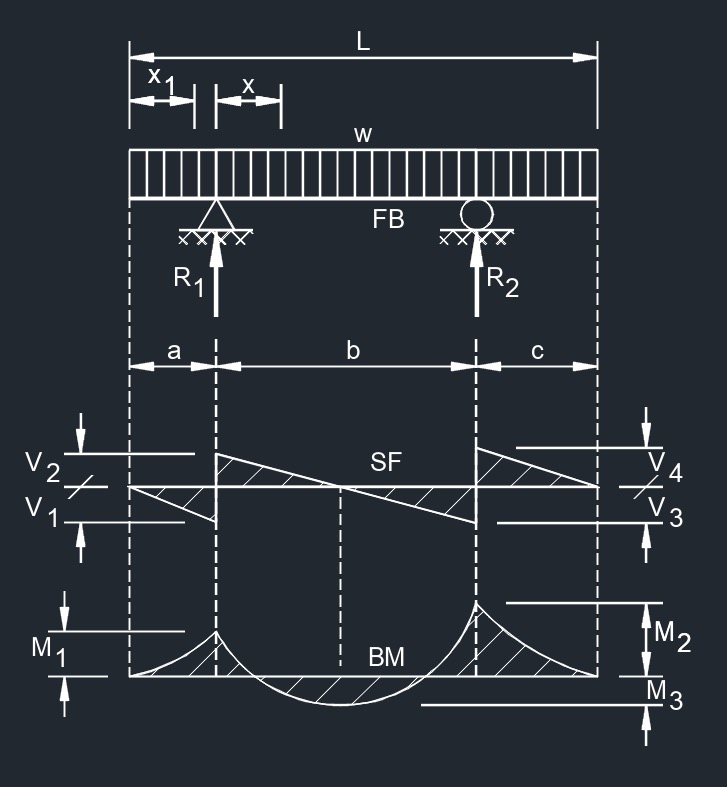

Uniform Load Partially Distributed at Any Point

Uniform Load Partially Distributed at Any Point  Uniform Load Partially Distributed at Each End

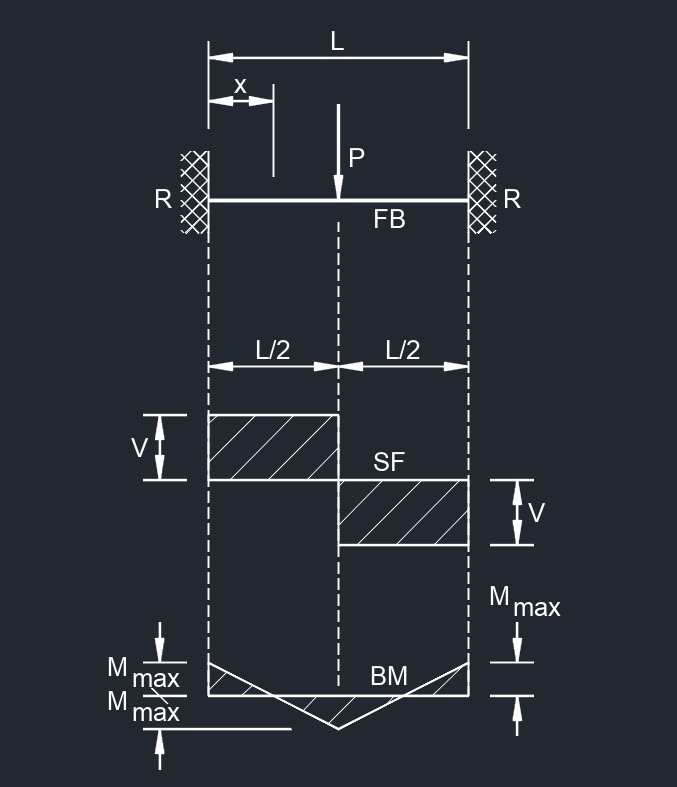

Uniform Load Partially Distributed at Each End  Concentrated Load at Center

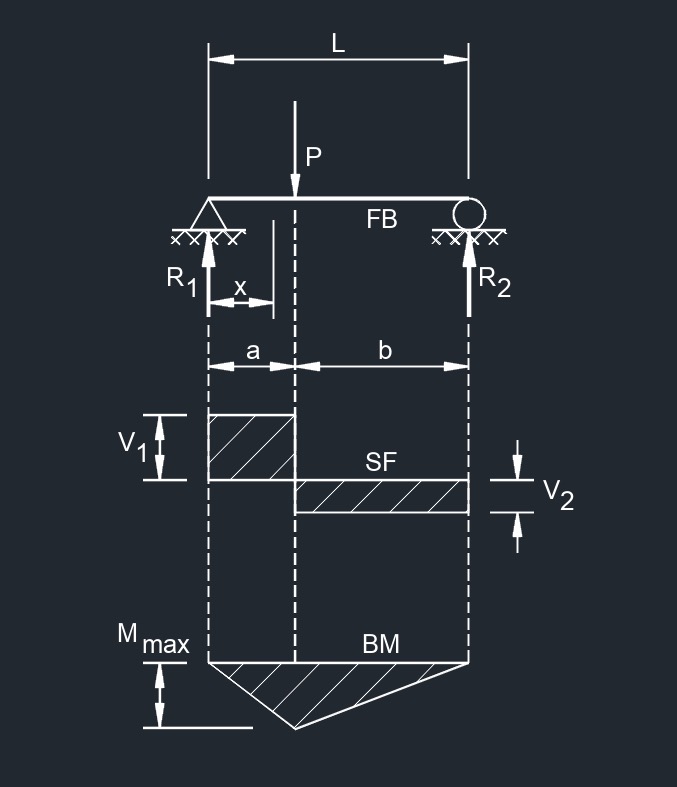

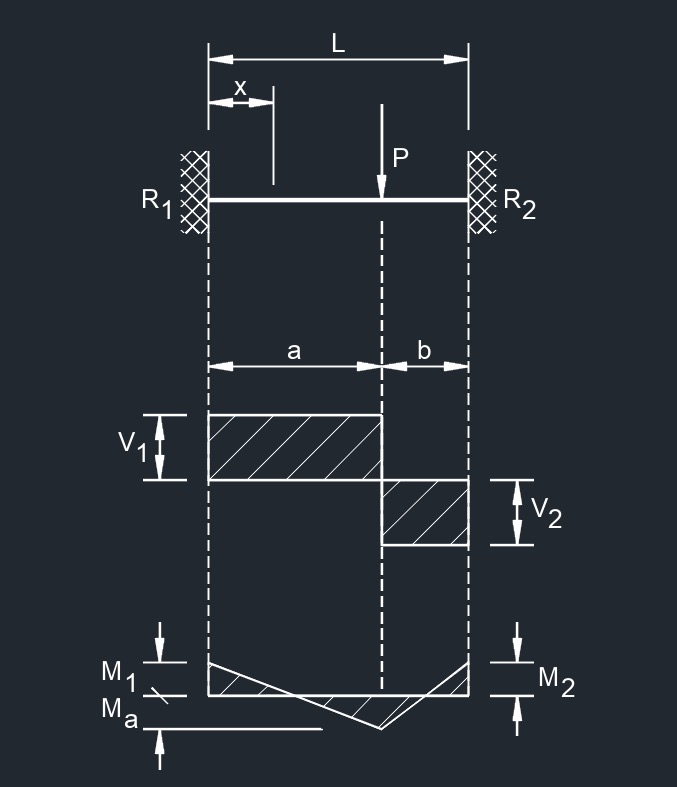

Concentrated Load at Center  Concentrated Load at Any Point

Concentrated Load at Any Point

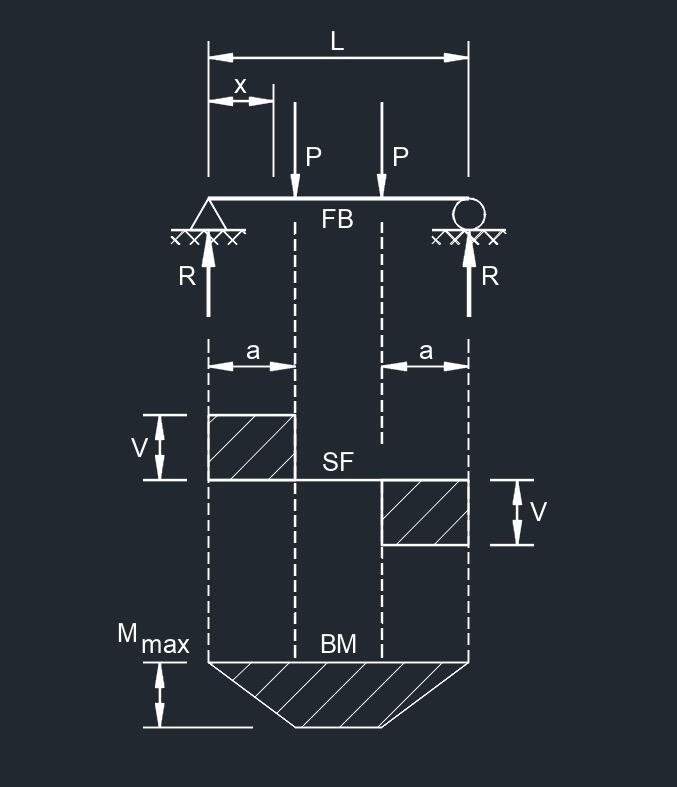

Two Point Loads Equally Spaced

Two Point Loads Equally Spaced  Two Equal Point Loads Unequally Spaced

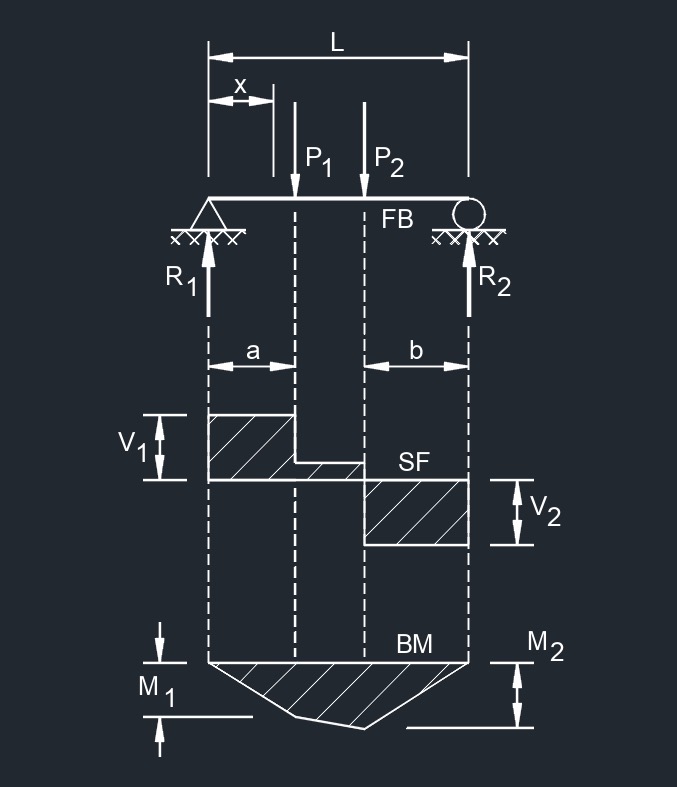

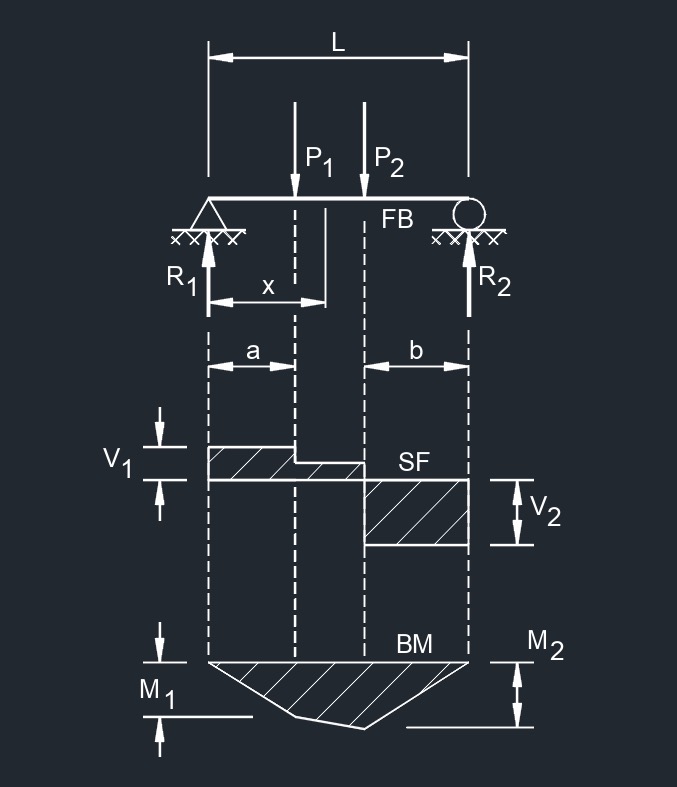

Two Equal Point Loads Unequally Spaced  Two Unequal Point Loads Unequally Spaced

Two Unequal Point Loads Unequally Spaced  Uniformly Distributed Load and Variable End Moments

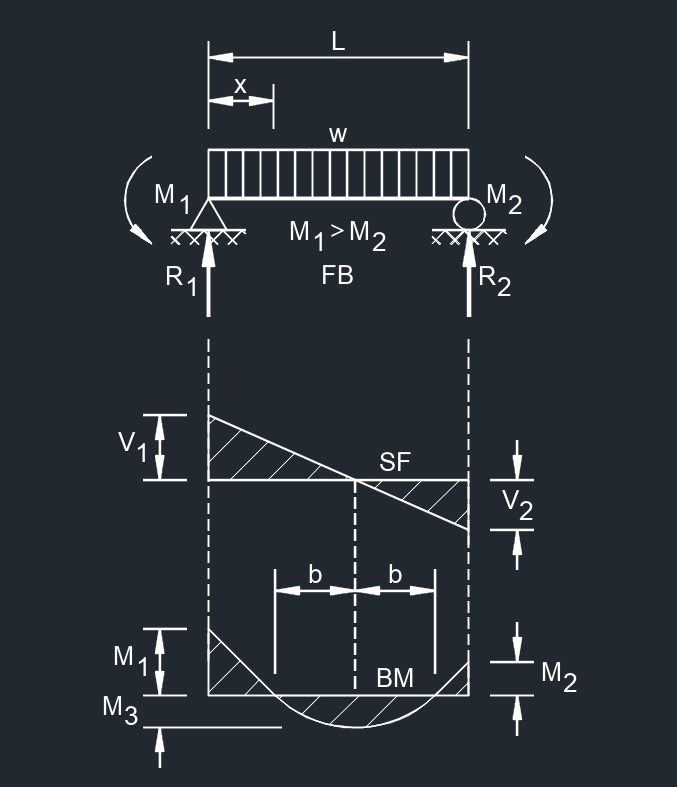

Uniformly Distributed Load and Variable End Moments

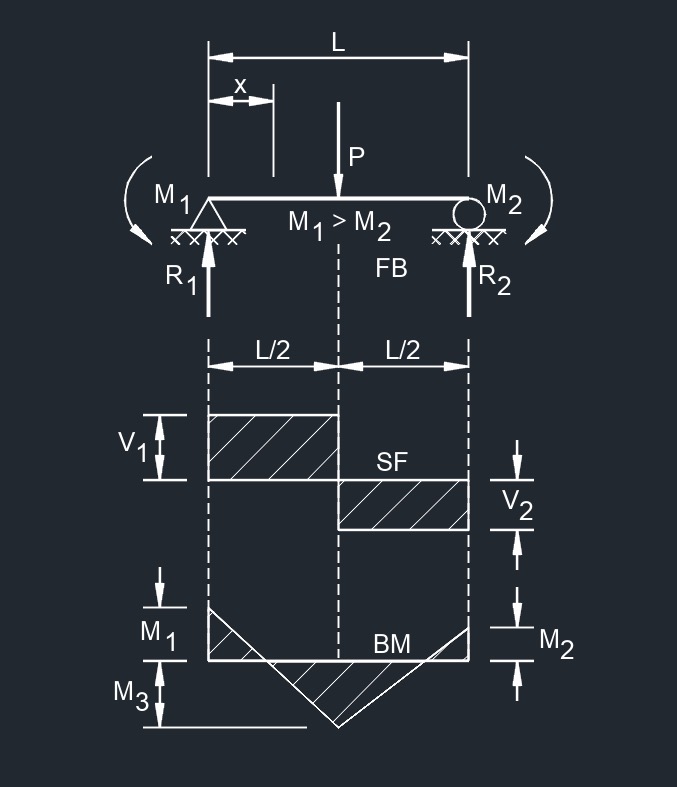

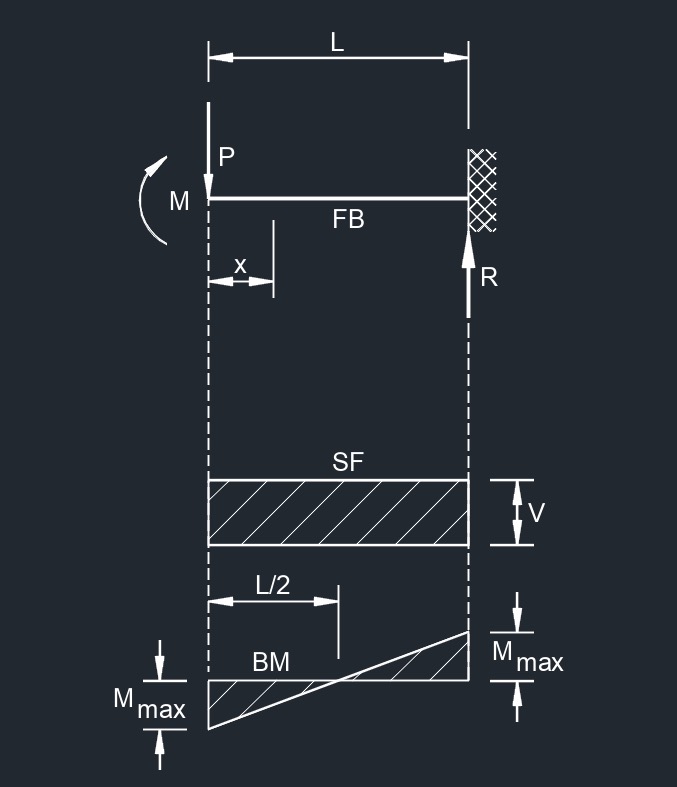

Central Point Load and Variable End Moments

Central Point Load and Variable End Moments

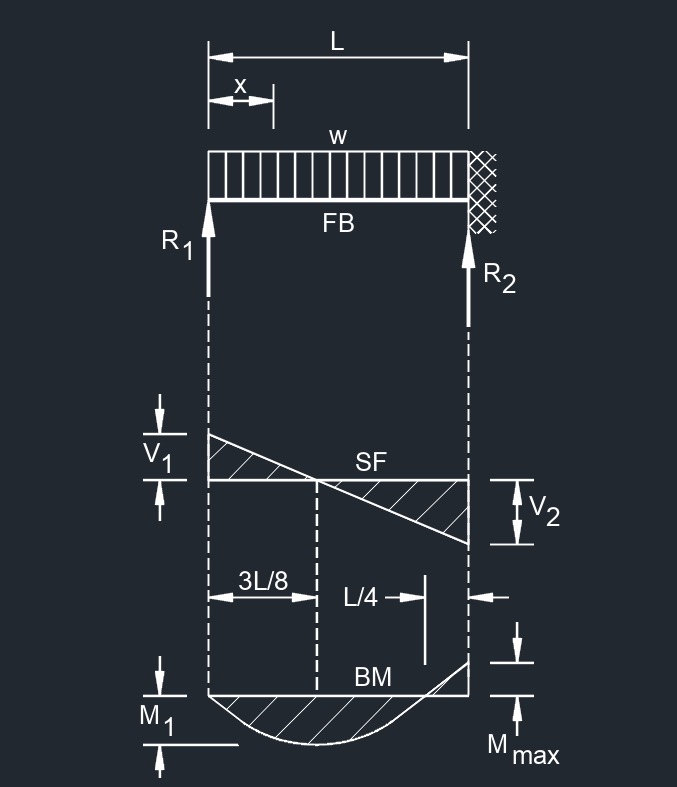

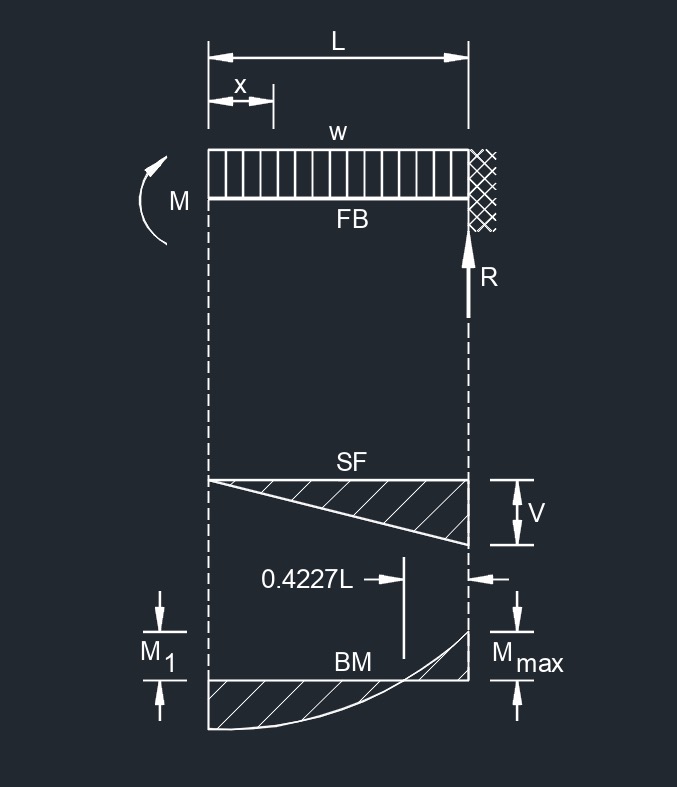

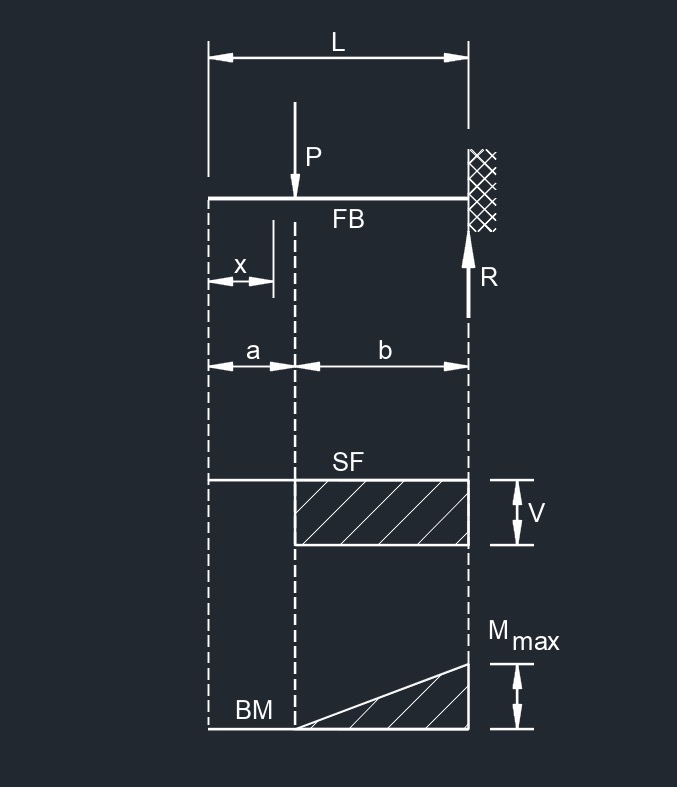

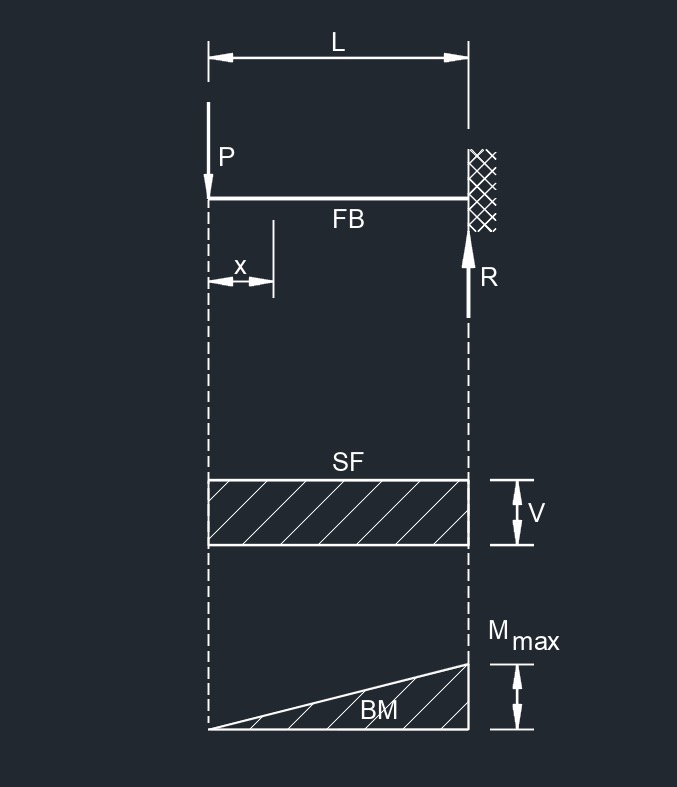

Beam Fixed at One End

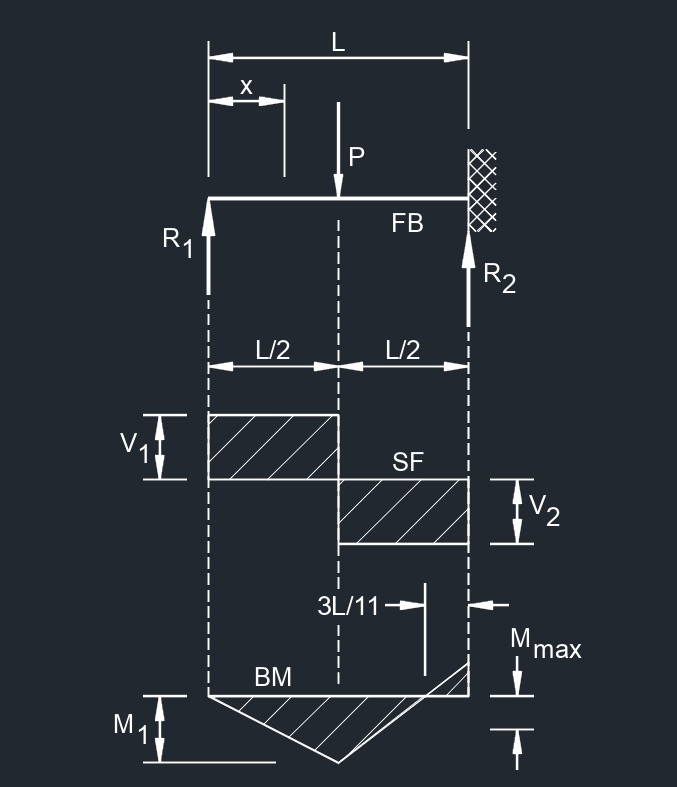

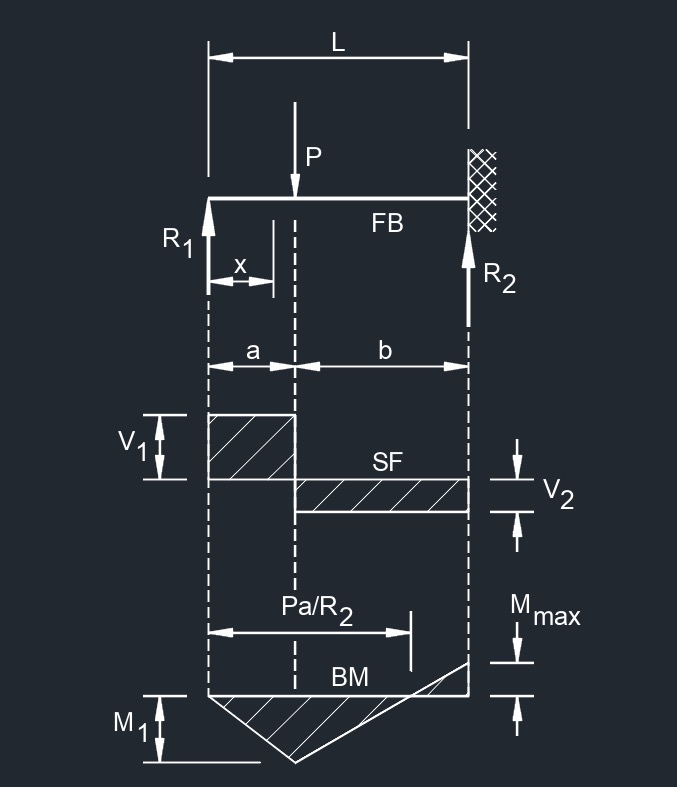

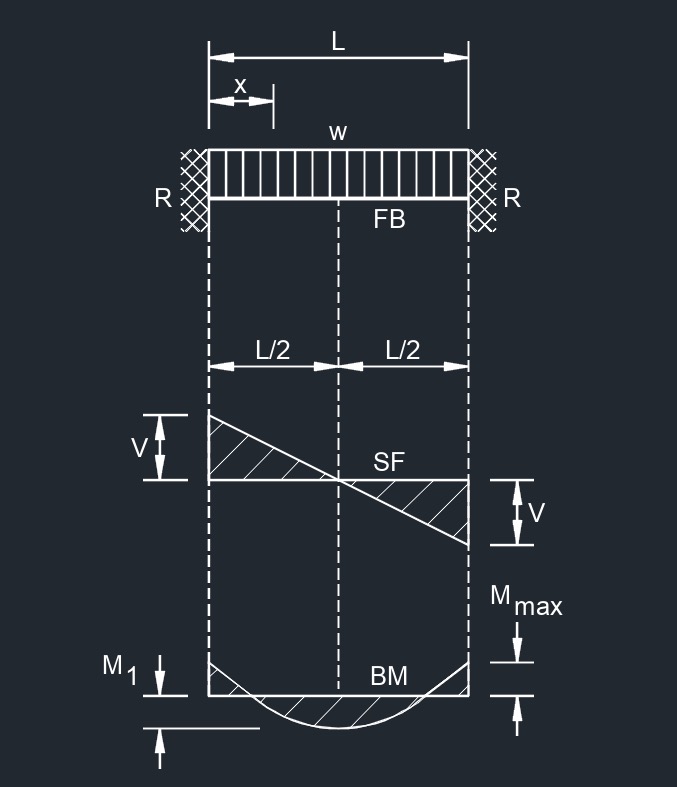

Beam Fixed at Both Ends

Uniformaly Distributed Load

Uniformaly Distributed Load Concentrated Load at Center

Concentrated Load at Center Concentrated Load at Any Point

Concentrated Load at Any Point

Cantilever Beam

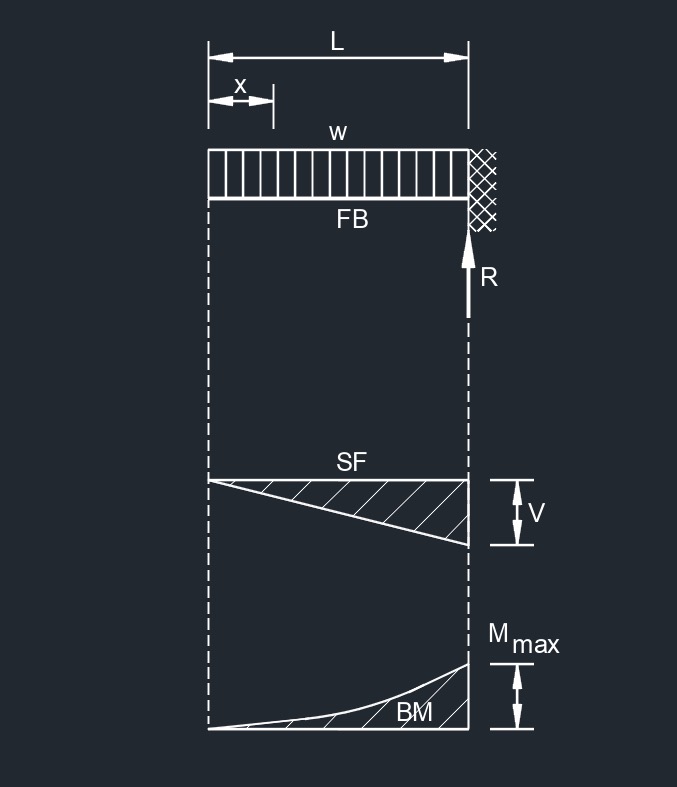

Uniformaly Distributed Load

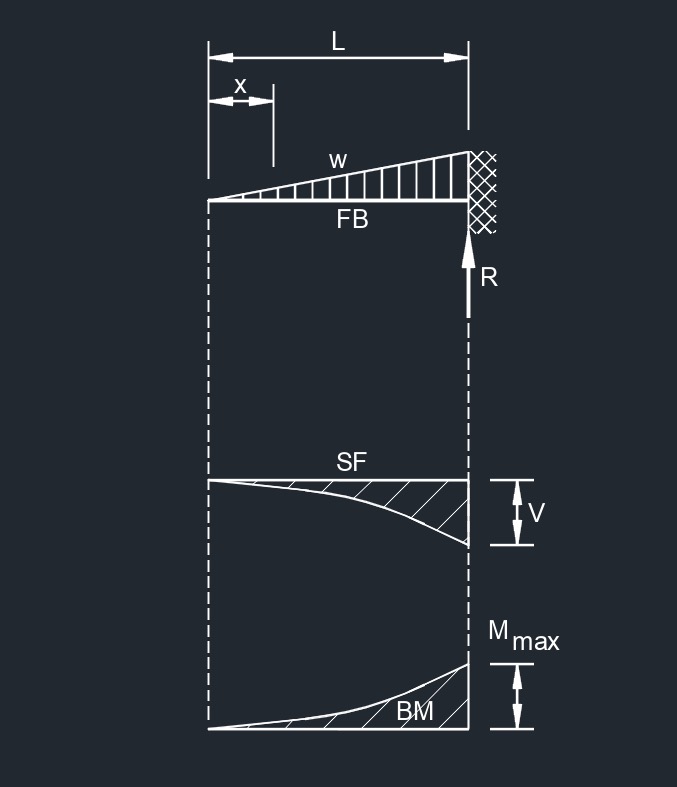

Uniformaly Distributed Load Load Increasing Uniformly to One End

Load Increasing Uniformly to One End  Uniformly Distributed Load and Variable End Moments

Uniformly Distributed Load and Variable End Moments  Concentrated Load at Any Point

Concentrated Load at Any Point

Concentrated Load at Free End

Concentrated Load at Free End Load at Free End Deflection Vertically with No Rotation

Load at Free End Deflection Vertically with No Rotation

Overhanging Beam

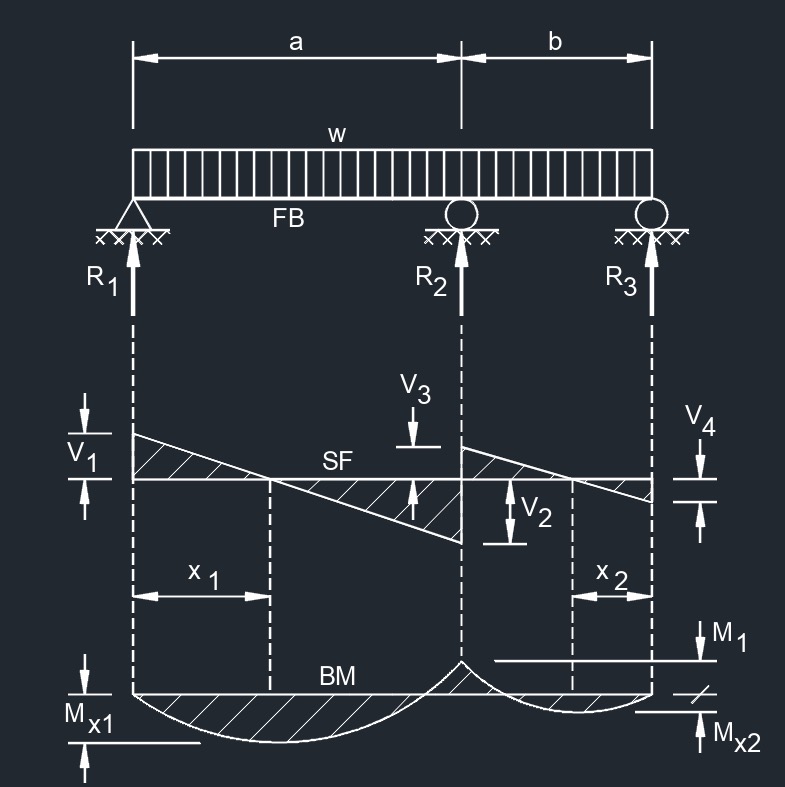

Uniformly Distributed Load

Uniformly Distributed Load  Uniformly Distributed Load on Overhang

Uniformly Distributed Load on Overhang  Uniformly Distributed Load Over Supported Span

Uniformly Distributed Load Over Supported Span  Uniformly Distributed Load Overhanging Both Supports

Uniformly Distributed Load Overhanging Both Supports

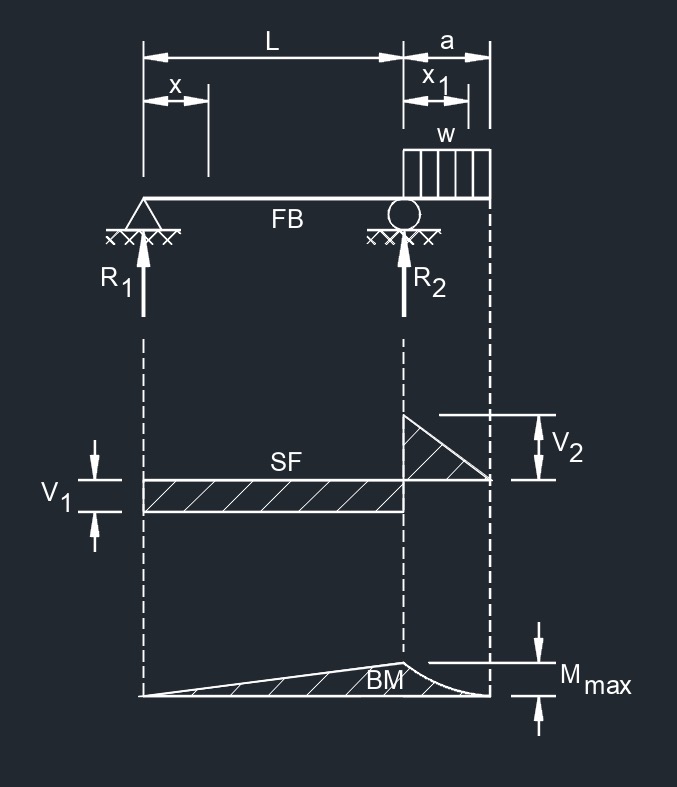

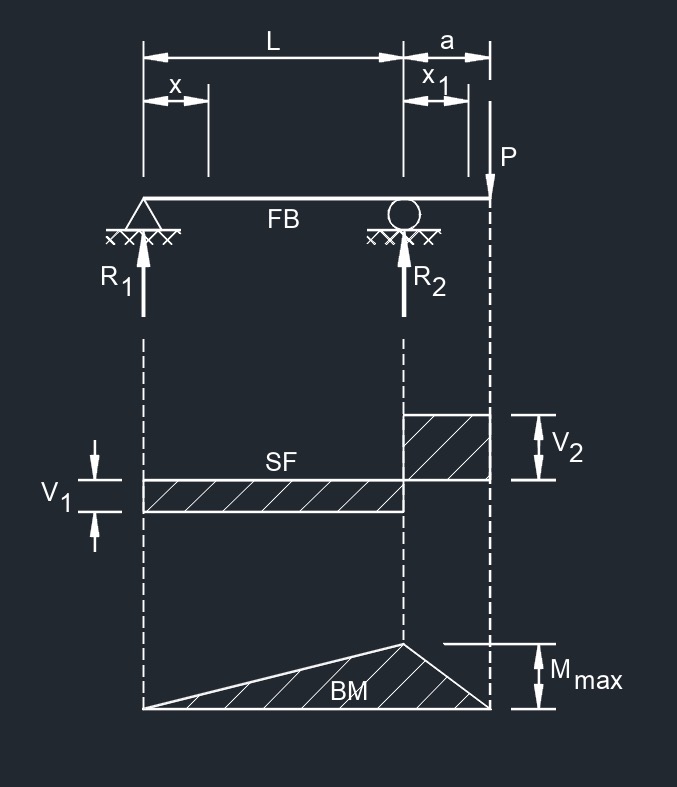

Point Load on Beam End

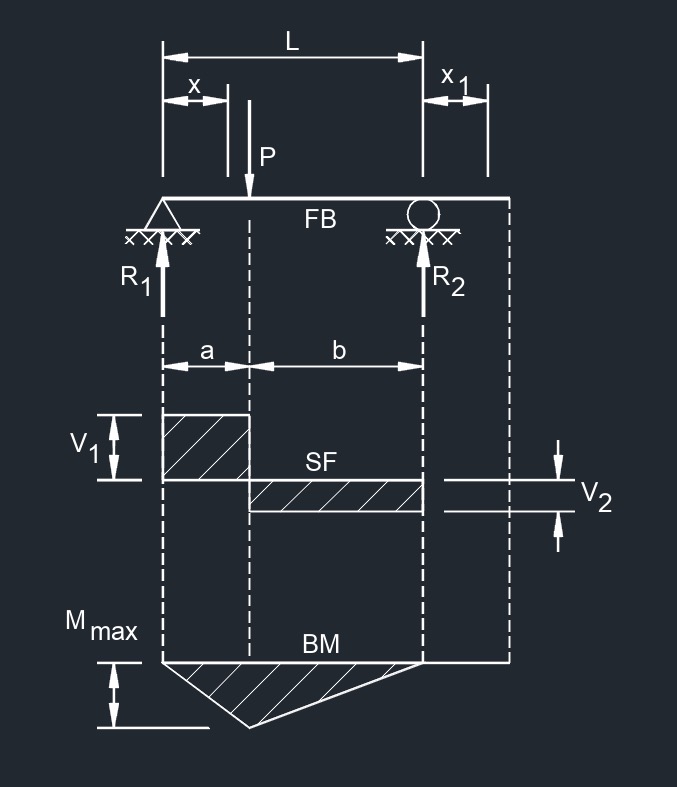

Point Load on Beam End Point Load Between Supports at Any Point

Point Load Between Supports at Any Point

Two Span Continuous Beam

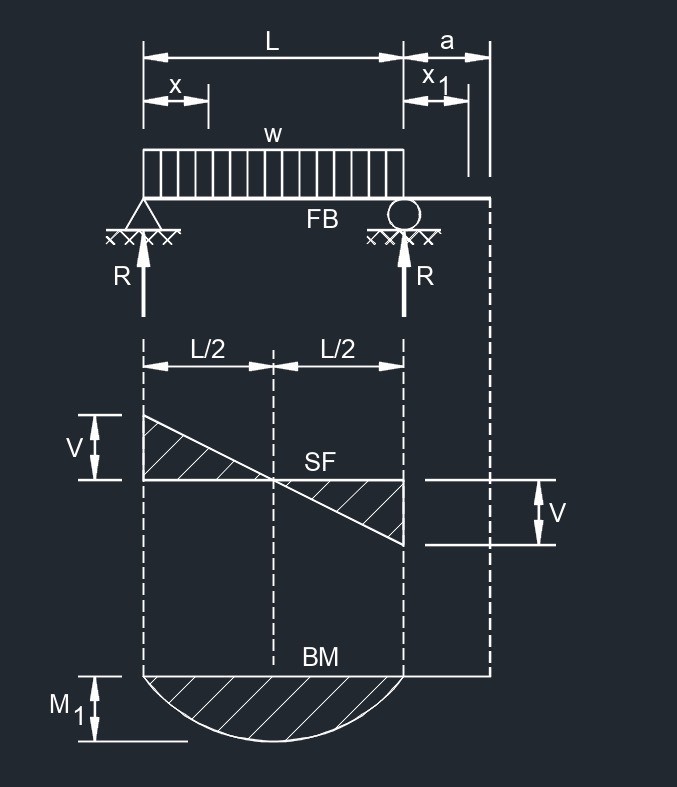

Equal Spans, Uniformly Distributed Load

Equal Spans, Uniformly Distributed Load  Equal Spans, Uniform Load on One Span

Equal Spans, Uniform Load on One Span  Unequal Spans, Uniformly Distributed Load

Unequal Spans, Uniformly Distributed Load  Equal Spans, Concentrated Load at Center of One Span

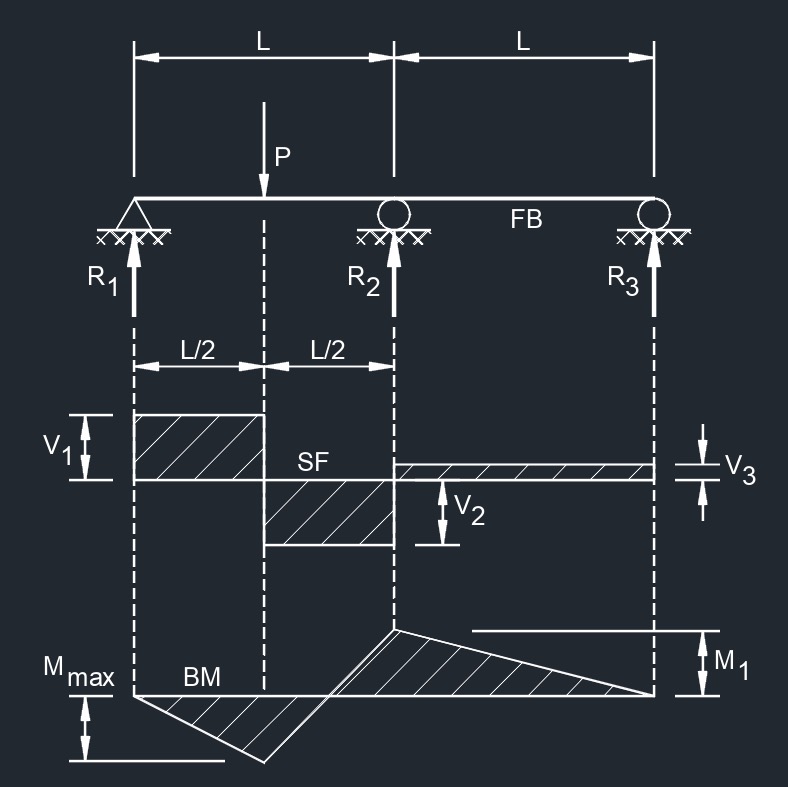

Equal Spans, Concentrated Load at Center of One Span

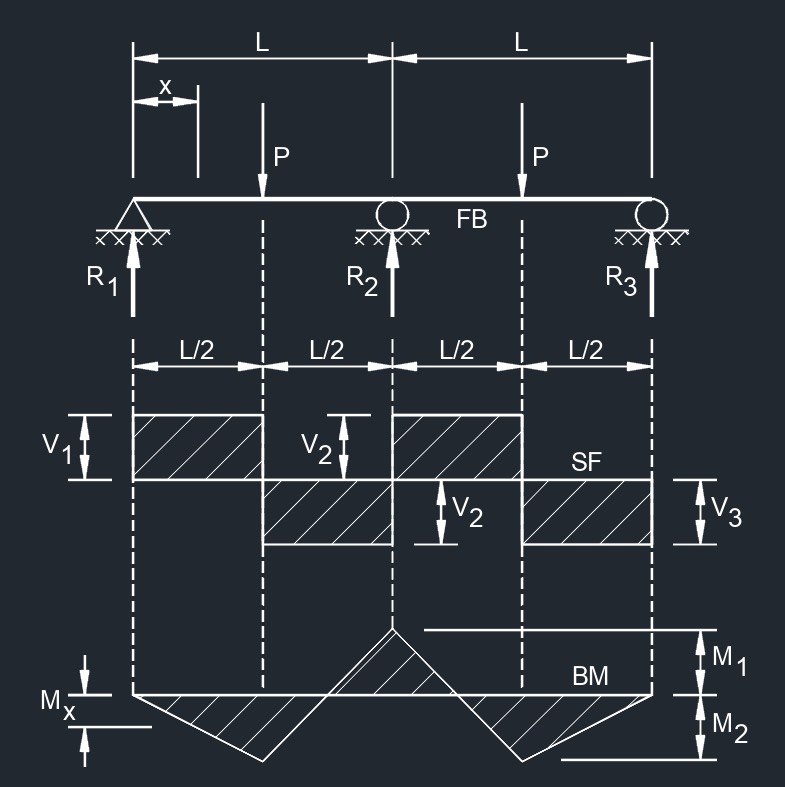

Equal Spans, Two Equal Concentrated Loads Symmetrically Placed

Equal Spans, Two Equal Concentrated Loads Symmetrically Placed Equal Spans, Concentrated Load at Any Point

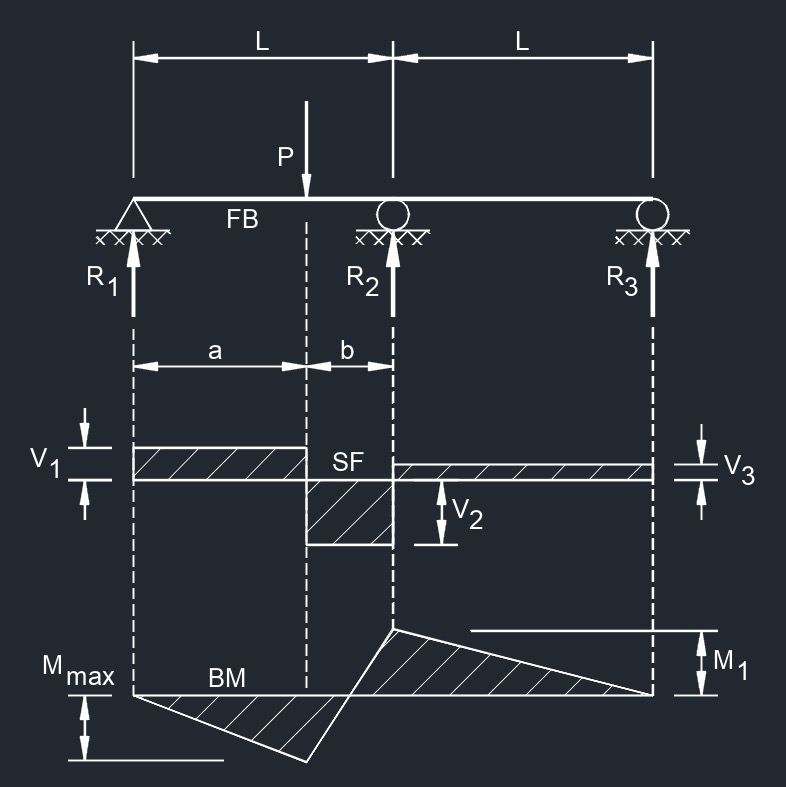

Equal Spans, Concentrated Load at Any Point Unequal Spans, Concentrated Load on Each Span Symmetrically Placed

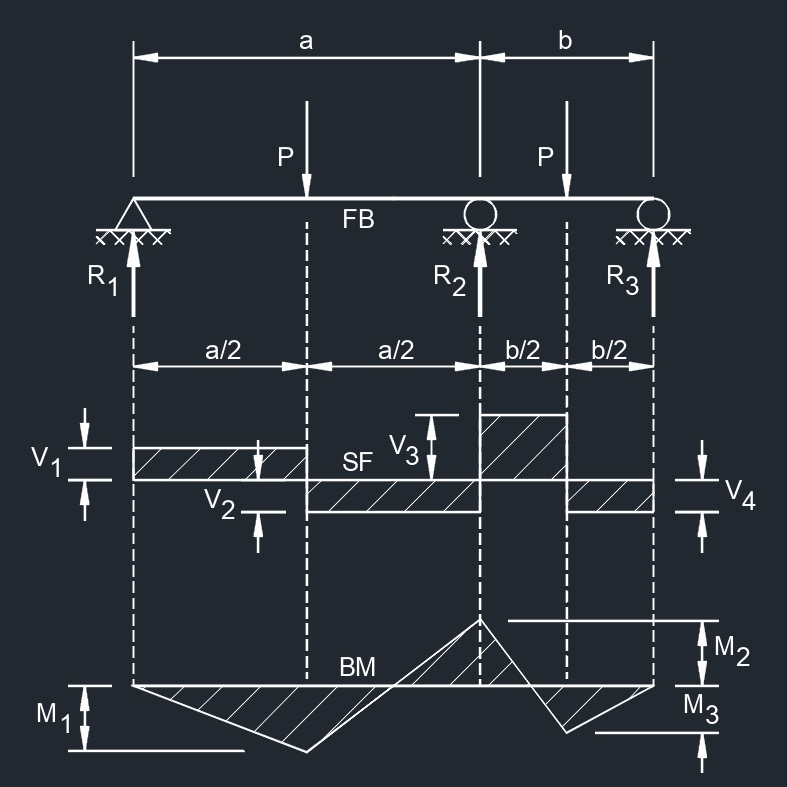

Unequal Spans, Concentrated Load on Each Span Symmetrically Placed

Three Span Continuous Beam

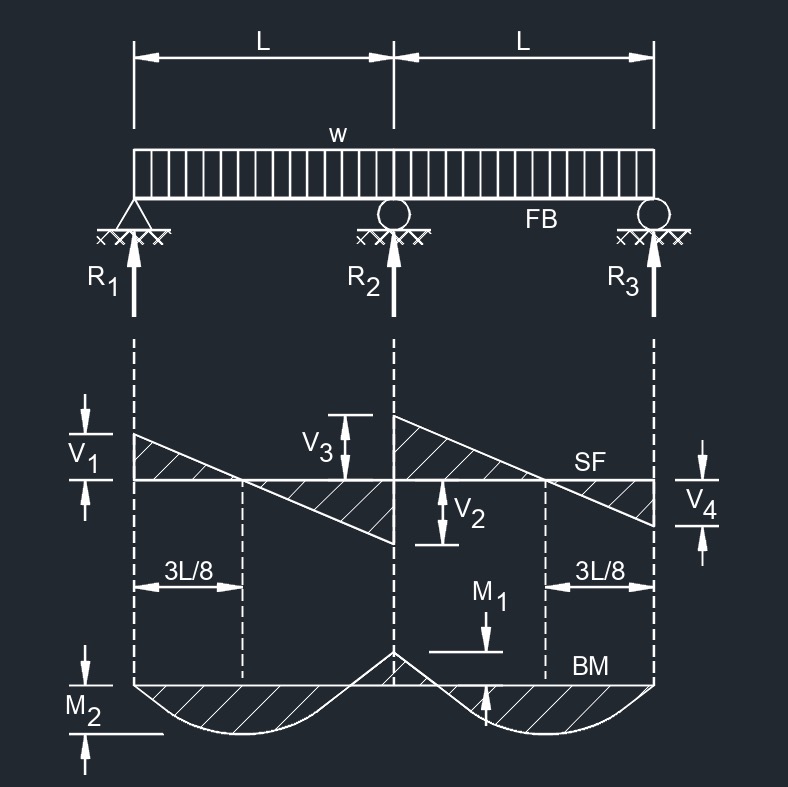

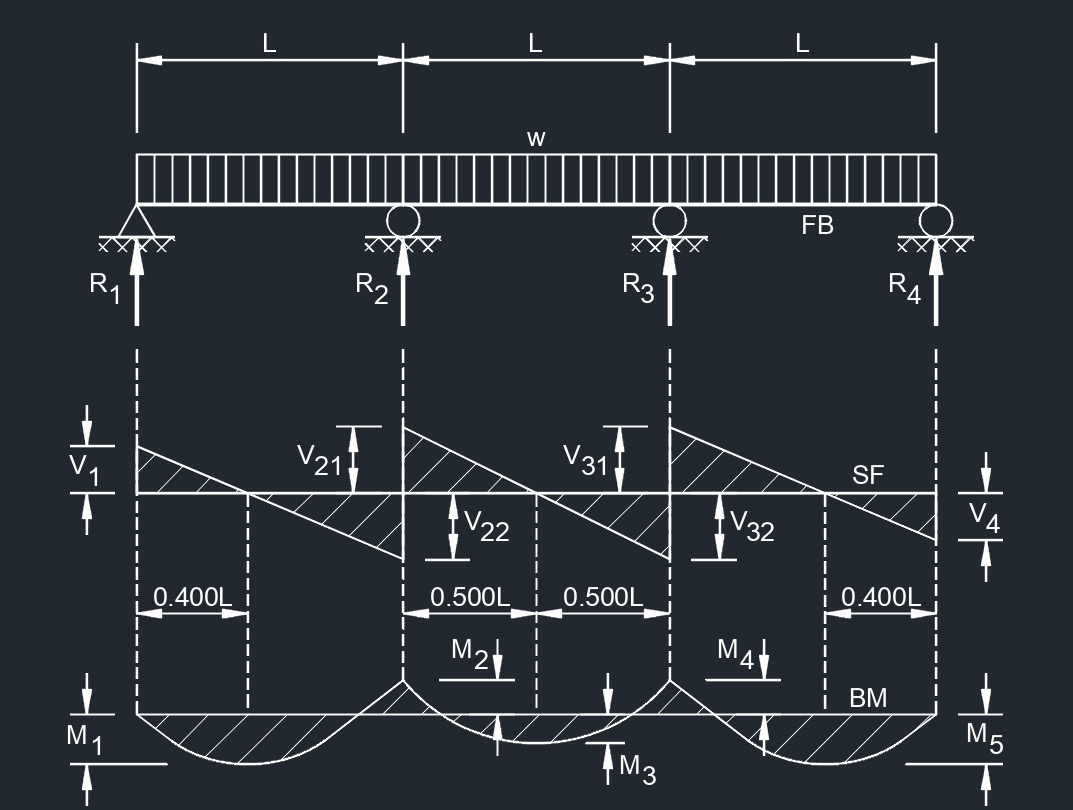

Equal Spans, Uniformly Distributed Load

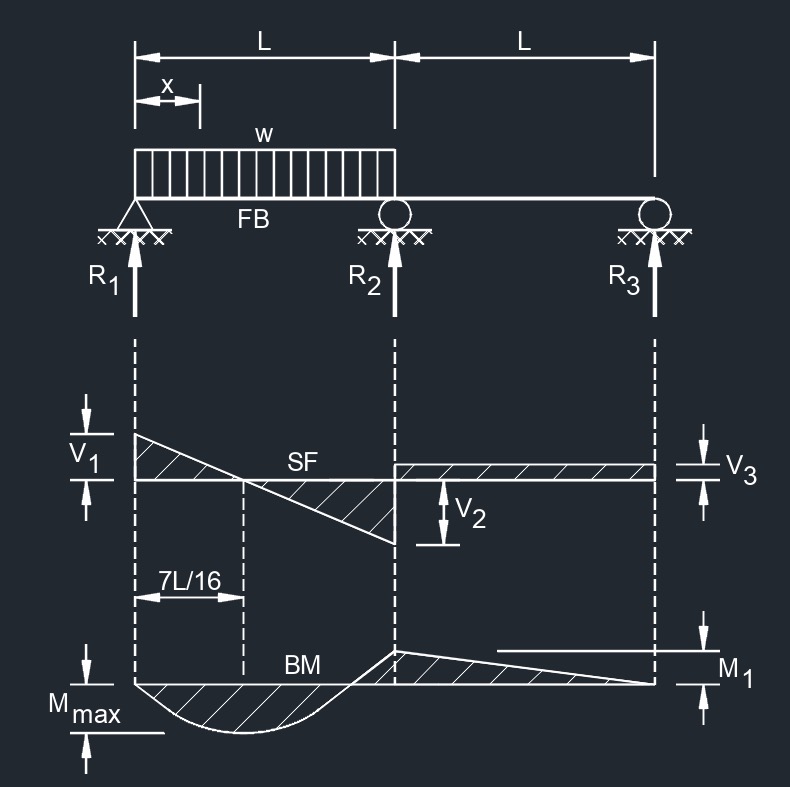

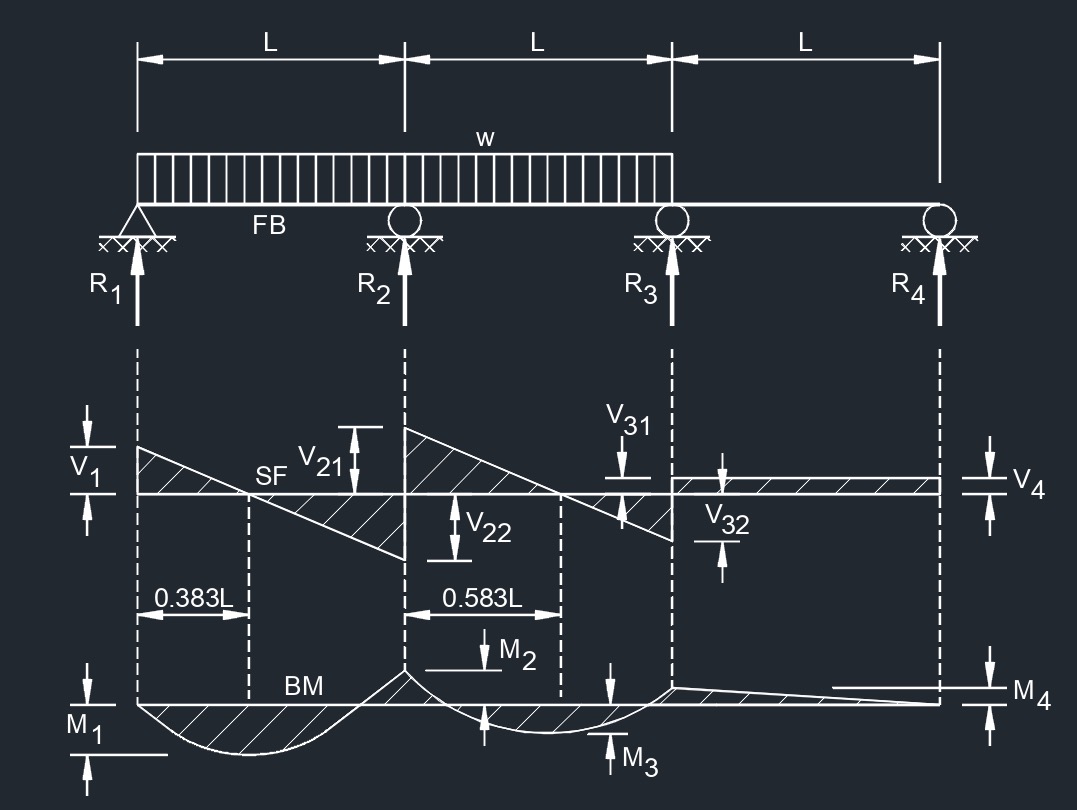

Equal Spans, Uniformly Distributed Load Equal Spans, Uniform Load on Two Spans to One Side

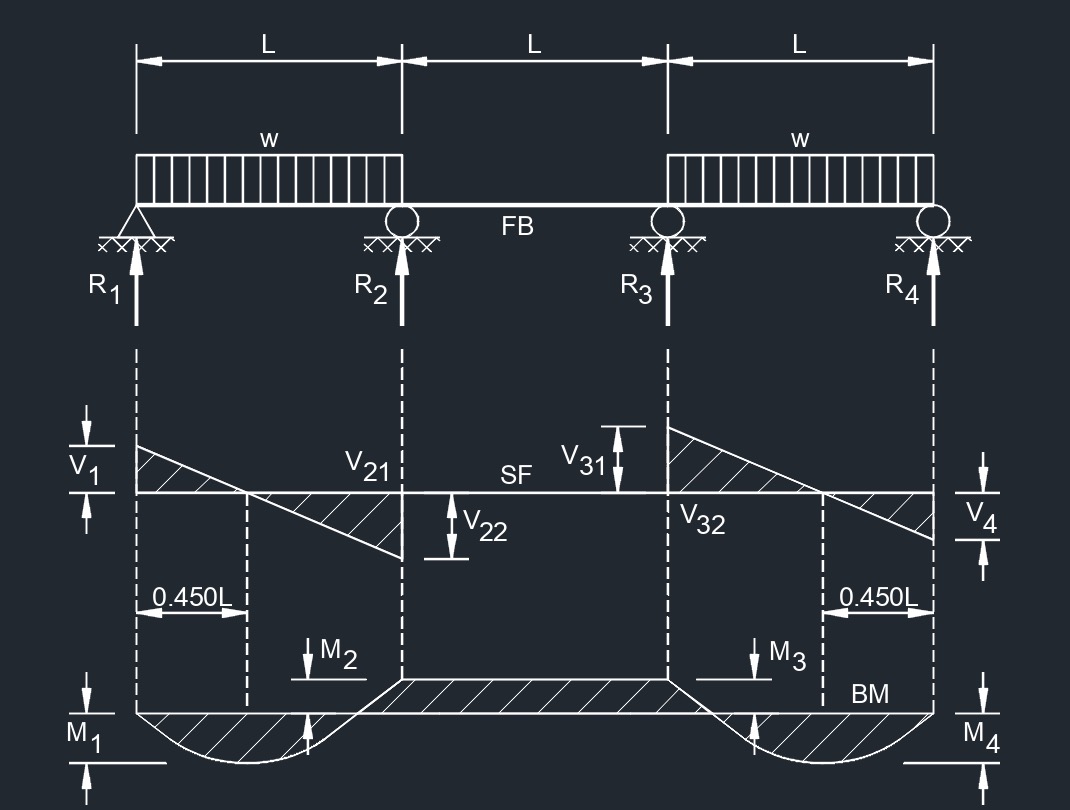

Equal Spans, Uniform Load on Two Spans to One Side Equal Spans, Uniform Load on Two Spans at Each End

Equal Spans, Uniform Load on Two Spans at Each End

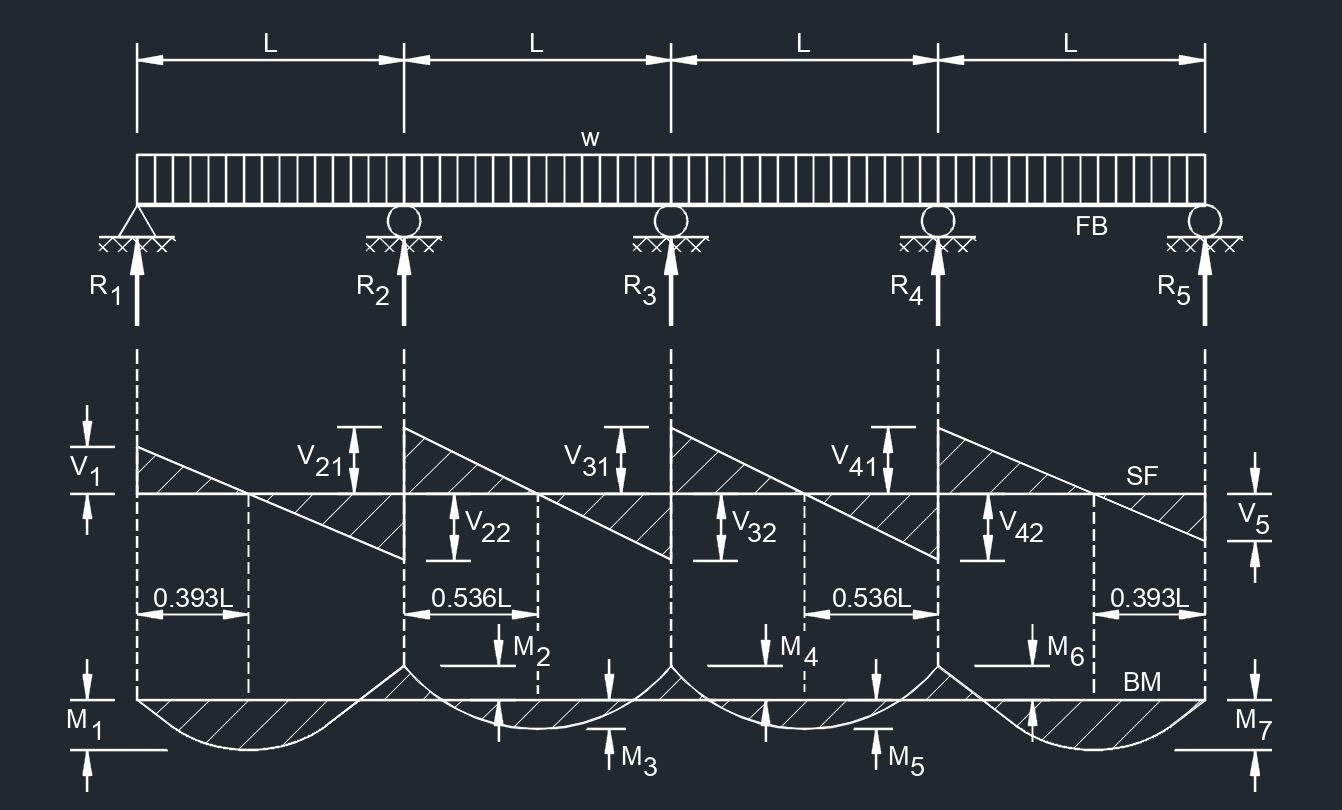

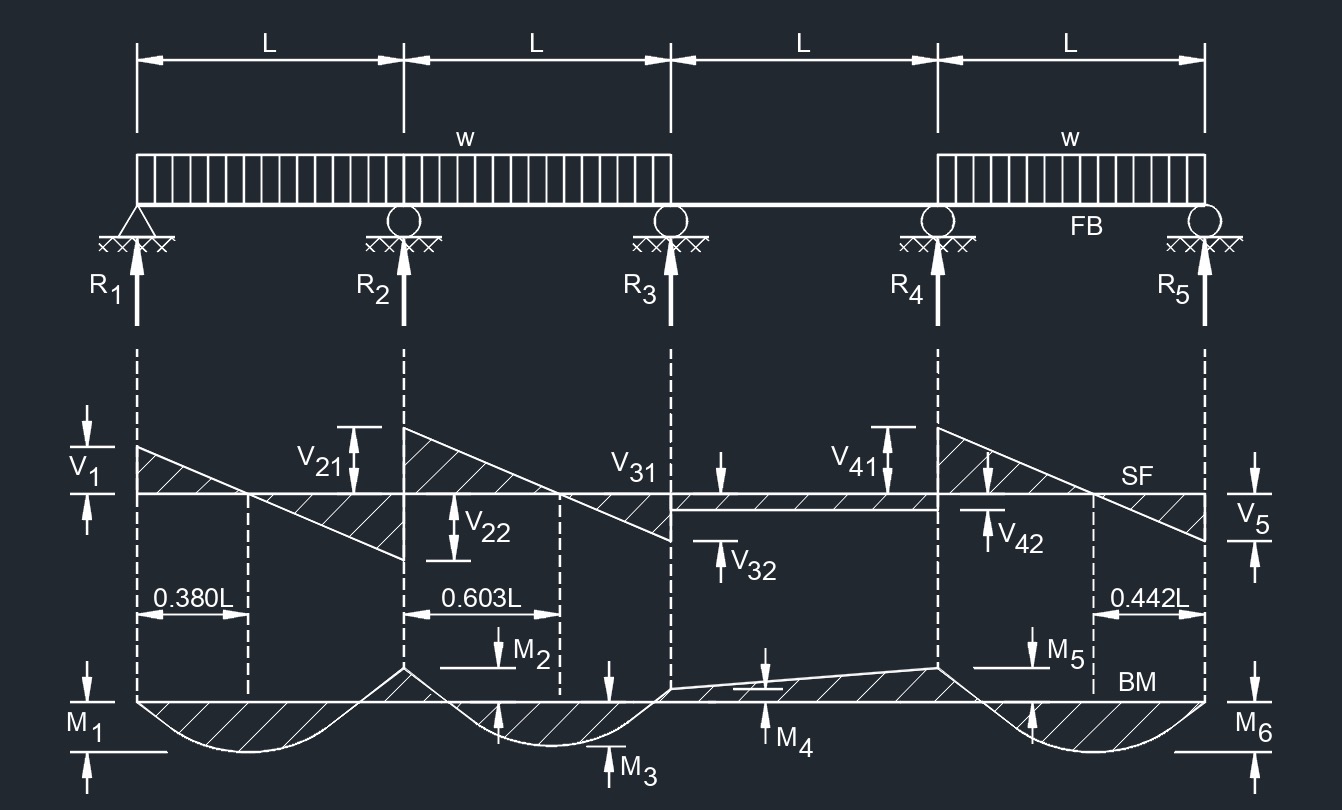

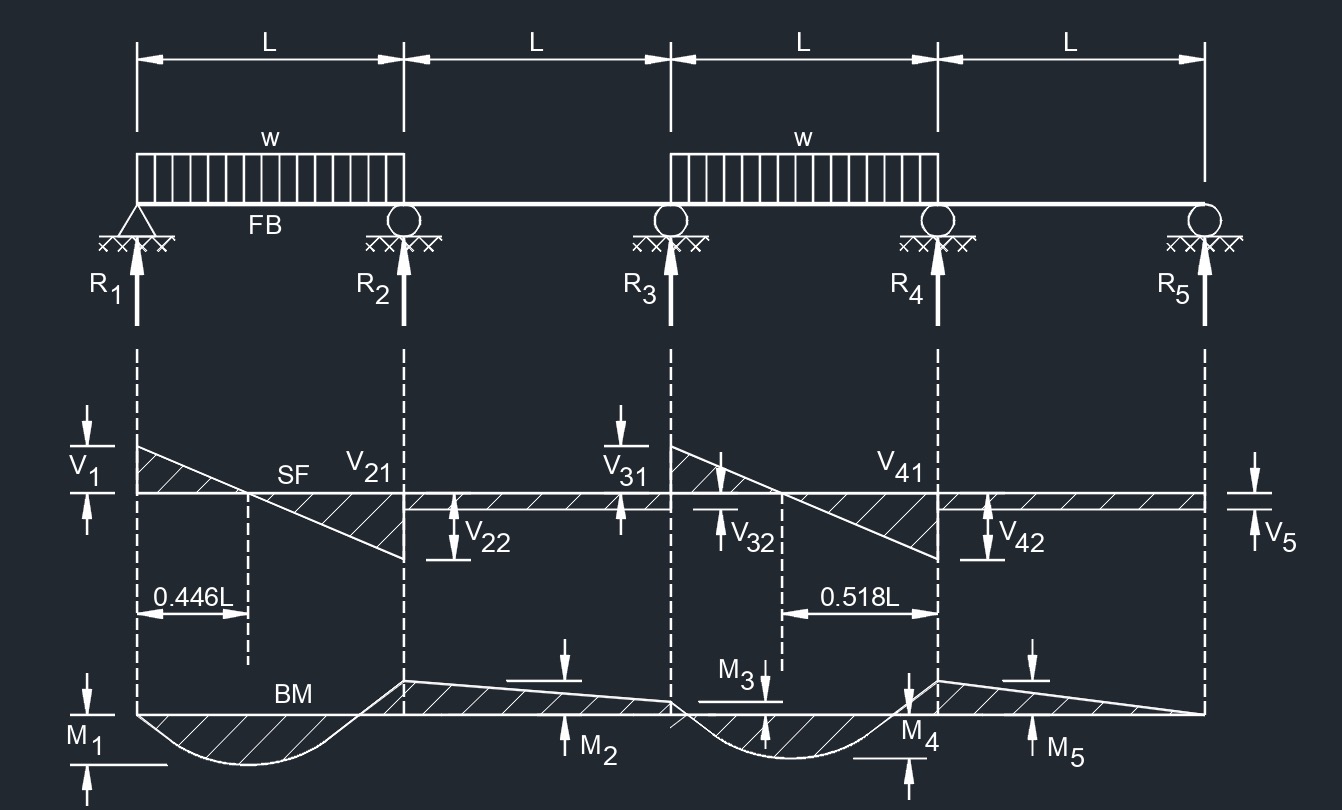

Four Span Continuous Beam

Equal Spans, Uniformly Distributed Load

Equal Spans, Uniformly Distributed Load Equal Spans, Uniform Load on Three Spans

Equal Spans, Uniform Load on Three Spans Equal Spans, Uniform Load on Two Spans

Equal Spans, Uniform Load on Two Spans

Nomenclature, Symbols, and Units for Beam Supports |

||||||

| Symbol | Greek Symbol | Definition | English | Metric | SI | Value |

| \(\Delta\) | Delta | deflection or deformation | \(in\) | \(mm\) | \(mm\) | - |

| \(a, b\) | - | distance to point load | \(in\) | \(mm\) | \(mm\) | - |

| \(w\) | - | highest load per unit length | \(lbf\;/\;in\) | \(N\;/\;m\) | \(N-m^{-1}\) | |

| \(x\) | - | horizontal distance from reaction to point on beam | \(in\) | \(mm\) | \(mm\) | - |

| \(w\) | - | load per unit length | \(lbf\;/\;in\) | \(N\;/\;m\) | \(N-m^{-1}\) | - |

| \(M\) | - | maximum bending moment | \(lbf-in\) | \(N-mm\) | \(N-mm\) | - |

| \(V\) | - | maximum shear force | \(lbf\) | \(N\) | \(kg-m-s^{-2}\) | |

| \(\lambda\) | lambda | modulus of elasticity | \(lbf\;/\;in^2\) | \(MPA\) | \(N-mm^{-2}\) | - |

| \(R\) | - | reaction load at bearing point | \(lbf\) | \(N\) | \(kg-m-s^{-2}\) | - |

| \(I\) | - | second moment of area (moment of inertia) | \(in^4\) | \(mm^4\) | \(mm^4\) | - |

| \(L\) | - | span length of the bending member | \(in\) | \(mm\) | \(mm\) | - |

| \(P\) | - | total concentrated load | \(lbf\) | \(N\) | \(kg-m-s^{-2}\) | - |

| \(W\) | - | total load \(\left( \frac{w\;L}{2} \right)\) | \(lbf\) | \(N\) | \(kg-m-s^{-2}\) | - |