Heat Exchanger

Heat Exchanger, Petroleum, Refinery Heat exchanger, abbreviated as HE or HEX, is a device used to transer heat from one medium to another at different temperatures. The heat transfer can be air or a liquid such as water or oil.

Heat exchanger, abbreviated as HE or HEX, is a device used to transer heat from one medium to another at different temperatures. The heat transfer can be air or a liquid such as water or oil.

A heat exchanger has many functions. They are critical to the process industries as they used to condense, heat, cool, or chill a fluid. It also can be used to change the phase of a fluid (liquid to vapor or vapor to liquid) like a boiler. Heat exchangers can be a direct contact HEX or an indirect contact type HEX.

In a direct contact heat exchanger, heat transfer continuously occurs by the mixing of two process streams. An example of this is a cooling tower, commonly found in power plants where a stream of hot air is consistently mixed with cooler water. The water cools the hot air and exits the top of the cooling tower. Warm water exits the bottom of the tower, is recollected, cooled and used again.

An indirect contact type heat exchanger transfers heat by maintaining a separation between the two process streams. Examples of an indirect contact type HEX are Shell and Tube Heat Exchangers and Air Cooled Heat Exchanger (also known as a fin-fan).

- See Articles - List of Tags / List of Categories / List of Articles / List of Glossaries / Nomenclature and Symbols / (See Heat Exchanger Glossary)

Science Branches

|

| Science |

| Applied Science |

| Engineering |

| Mechanical Engineering |

|

Heat Exchanger Design Classification

The construction of the heat exchanger is to exchange or transfer heat between the fluids used. The function of heat exchanging device depends on its purpose of use. It can be used either to heat a fluid or even to cool down a fluid.

Extended Surface Heat Exchanger - The design of finned surfaces enables to improve the heat transfer coefficient by distributing the fluid flow apart from increasing the surface area. Gas flow patterns separates moisture efficiently. Selection of the best combination of materials suitable for process and required duty conditions ensures most economic design allied with the longer service life. Additional surface protection against corrosion can also be incorporated in the form of galvanizing on steel.

Finned Plate Heat Exchanger - This exchanger consist of a series of fin surfaces sandwiched between sheets stacked together. The fin can increase efficient heat transfer area and transfer heat to fluid through the sheets.

- Fin-fan Heat Exchanger (Air Cooled Heat Exchanger) - This heat exchanger forces air over a set of coils to cool the process.

- Horizontal Forced Draft Air Cooled - The fans are located below the bundle and push air upwards.

- Horizontal Induced Draft Air Cooled - The fan is located above the tube bundle and air is induced or pulled through the finned tubes.

- Vertical Air Cooled - The fan is located at the front of the bundle and the air is forced through vertically.

- A Frame Forced Draft Air Cooled - The fans are located below the bundle, the bundle is split in two, the left and right side, an A shaped frame, then the air is forced towards the bundles.

- V Frame Induced Draft Air Cooled - The fans are located above the bundle, the bundle is split in two, the left and right side, in a V shaped frame, then the air is pulled through the finned tubes.

Finned Tube Heat Exchanger - This is a tube with extended outer surface area or fins to enhance the heat transfer rate from the additional area. Finned tubes with extended outer surface area enhance the heat transfer rate by increasing the effective heat transfer area between the tubes and surrounding fluid. The fluid surrounding finned tubes maybe process fluid or air.

- Longitudinal Finned Tube - These tubes are best suited for applications where the flow outside the tubes is expected to be streamlined along the tube length.

- Double Pipe Heat Exchanger

- Traverse Finned Tube - They normally used for gas flows or turbulent flows and for cross flow type exchangers or shell and tube heat exchangers.

- Shell and Tube Heat Exchanger

Plate Heat Exchanger - Metal plates are used to transfer heat between two fluids. The plate is a metal shell, with spaces inside each plate that act as hallways for fluids to travel through. With a plate heat exchanger, there is a greater surface area in contact with the fluids, so it has better rates of heat transfer compared to all other types. Although plate heat exchangers can be more expensive, the efficiency gained by the design is a big plus.

- Brazed Plate - These are used in many industrial and refrigeration applications. Since they use stainless steel plates with copper brazing, they are highly resistant to corrosion.

- Gasketed Plate - These exchangers use high-quality gaskets to seal plates together and protect against any leaks. Plates can easily be removed for cleaning, expansion, or replacement.

- Welded Plate - The welded plate is similar to gasket plate heat exchangers, but all the plates are welded together. Since the plates are welded together, cleaning the plates isn’t possible with plate and frame heat exchangers.

- Semi-welded Plate - This exchanger consist of a mixture of welded and gasketed plates. The two pairs of plates are welded together and then gasketed to the other joints.

Regenerative Heat Exchanger - A type of heat exchanger where heat from the hot fluid is intermittently stored in a thermal storage medium before it is transferred to the cold fluid. It has a single flow path in which the hot and cold fluids alternately pass through. This exchangers normally increase in efficiency with the time allowed for the temperature exchange to occur and so it can run at lower temperatures. A recouperator exchanger normally requires a higher temperature metallic or plastic heat exchanger but can be more effective over shorter exchange periods.

- Static (Fixed Matrix or Fixed Bed) - This type transfers heat between two fluid streams. The fluid streams flow in and out of the matrix through different ports, with the direction of flow being controlled by valves or other mechanisms.

- Dynamic (Rotary) - This use a rotating wheel or drum to transfer heat between two fluid streams.

Spiral Plate Heat Exchanger (Coil) - The spiral exchanger is made by rolling two long metal plates around a center core to form two concentric spiral flow passages, one for each fluid. The plate edges are welded shut so that each fluid stays within its own passage and there is no flow bypassing or intermixing. Channel plate width and spacing are optimized for the specified duty, maximum heat transfer, and ease of access. The plate gap is maintained by welded spacer studs although some designs do not require them.

- Spiral Flow Both Sides

- One Side in Cross Flow, One Side in Spiral Flow

- Combined Cross - Spiral Flow

Tubular Heat Exchanger - This exchanger is used to warm or cool a product by exchanging heat between the process fluid and a service fluid. The hot or cold service fluid flows around the tubes within the exchanger and heat is transferred between the product and the media. The rate of heat transfer is dependent on the tubular heat exchanger configuration, temperature differential, size of tubes, turbulence in the flow and flow velocity.

- Double Pipe Heat Exchanger - Used for the transfer or exchange of heat between two liquids without mixing them. They consist of two or more concentric, cylindrical pipes or tubes, one larger and the other smaller. One fluid flows inside the tube and the other fluid flows outside.

- Pipe Coil Heat Exchanger - Coil exchangers are frequently used for heating or cooling product in processing plant tanks and vessels. Tube coils provide an economical and straightforward method of obtaining heat transfer surface area. Tube coils are made by rolling lengths of tubing into helixes or double helixes in which the inlet and outlet are located side by side.

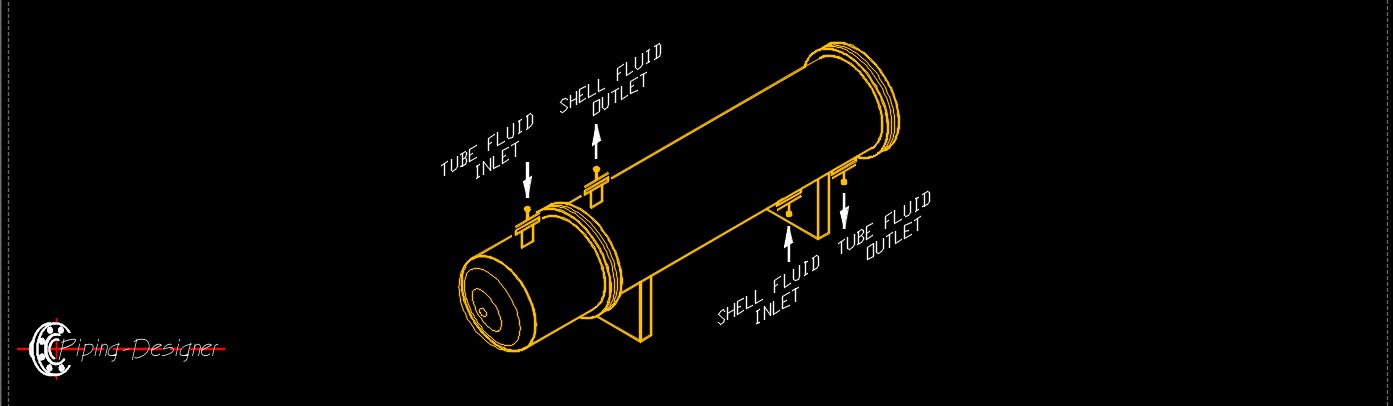

- Shell and Tube Heat Exchanger - Has multiple tubes in which the two working fluids exchange heat by thermal contact which is placed within a cylindrical shell. As such, one fluid flows inside the tubes and the other through the shell.

- One Pass Shell

- Two Pass Shell

- Split Flow

- Double Split Flow

- Divided Flow

- Kettle - Reboiler

- Cross Flow

- Spiral Tube Heat Exchanger - A coil assembly fitted in a compact shell that optimizes heat transfer efficiency and space. Spiral coil assembly has welded tube to manifold joints and uses stainless steel as a minimum material requirement for durability and strength. The coil assembly is welded to a head and fitted in a compact shell. The spaces or gaps between the coils of the spiral tube bundle become the shell side flow path when the bundle is placed in the shell. Tube side and shell side connections on the bottom or top of the assembly allow for different flow path configurations.

Heat Exchanger Advantages and Disadvantages | |

|---|---|

| Advantages | Disadvantages |

|

|

Heat Exchanger Design Consideration

Transfer Process - Heat exchangers are classified into direct and indirect contact type exchangers.

- Direct Contact - The two fluids are not separated by a wall. The fluids come into direct contact to exchange heat between each other and exit through their respective outlet nozzles or line. Due to direct heat exchange, very close temperatures can be attained.

- Indirect Contact - The fluid streams remain separate, and the heat transfer takes place continuously through a separating wall.

Flow Arrangement - The choice of a particular flow arrangement is dependent upon required exchanger effectiveness, exchanger construction type, upstream and downstream ducting, packaging envelope, and other design criteria.

- Counter Flow - The direction of the fluid is parallel but opposite to the other are known as counter current type heat exchangers. They usually have the highest heat exchange and greatest temperature change.

- Cross Flow - The flow of the fluids inside the heat exchanger is perpendicular to each other, they are called cross flow. In terms of efficiency, a cross-flow heat exchanger gives better efficiency than the parallel flow configuration type heat exchanger.

- Parallel Flow - A double pipe heat exchanger can be operated in parallel flow. Similarly a shell and tube heat exchanger can be operated in approximately parallel flow by having both fluids enter at one end and exit at the other end. With parallel flow the temperature difference between the two fluids is large at the entrance end, but it becomes small at the exit end as the two fluid temperatures approach each other.

- Spiral Flow - These exchangers use thin plates or tubes to keep two fluids of different temperatures apart while allowing energy to flow from hot to cold through the wall. The energy transfer acts to change the temperatures of the two media. The hotter one becomes cooler and the colder one becomes hotter.

Pass Arrangement - Refers to the movement of a fluid from one end of the heat exchanger to the other.

- Single Pass - The fluid flows through the heat exchanger along its length once.

- Multiple Pass - The fluid flows through the heat exchanger along its length and then it’s reversed to flow again through the whole length again. In multi pass arrangements the flow can pass along the length of heat exchanger 2 or more times. Multi pass arrangements are used when design of heat exchanger results in extreme length, significantly low velocities or low effectiveness.

Flow Rate - Flow rate determines the flow area. The higher the flow rate, the higher will be the crossflow rate area. Higher flow area is required to limit the flow velocity through the conduits and flow passage. The higher velocity is limited by pressure drop, impingement, and erosion. Sometimes, a minimum flow velocity is necessary to improve heat transfer to eliminate stagnant areas and to minimize fouling.

Pressure - The design pressure is important to determine the thickness of the pressure components. The higher the pressure, the greater the required thickness. The pressure level of the fluids has a significant effect on the type of unit selected. At lower pressures, the vapor phase volumetric flow rate is higher and the low allowable pressure drops may require a design that maximizes the area available for flow. At higher pressures, the vapor phase volumetric flow rates are lower and allowable pressure drops and greater. Normally, higher heat transfer rates are obtained by placing the low pressure gas on the outside of tubular surfaces.

Tempereature - The effective temperature driving force is a measure of the actual potential for heat transfer that exists at the design conditions. With a counterflow arrangement, the effective temperature difference is defined by the log mean temperature difference. For flow arrangements other than counterflow arrangement, the log mean temperature difference must be corrected by a correction factor.

Temperature Differential - The difference between the hot fluid and coolant is very important when designing a heat exchanger. The coolant always needs to be at a lower temperature than the hot fluid. Lower coolant temperatures will take more heat out of the hot fluid than warmer coolant temperatures.

Tempereature Cross Over - This is a term used to describe the scenario where the temperatures of both circuits in a liquid cooled heat exchanger begin to cross over. This can be an important factor in a heat exchanger design as the efficiency of a cooler will be significantly reduced when the temperatures cross over.

Heat Transfer - The transfer of heat in heat exchangers is a combination of both conduction and convection. The driving force of heat transfer is the temperature difference between the inlet and outlet temperatures minus the inlet and outlet temperature of the process stream.

- Temperature - The amount of heat or cold, but it is neither heat or cold. Temperature is expressed as a number that is related to energy and porportional to a type of energy, but it is not energy. Temperature is a number related to the average kineric energy, but is not kinetic energy.

- Conduction - Heat transfer by conduction is the second most efficient form of heat transfer after mixing. It is the flow of energy between two objects, or within one object, where there is a temperature differential. Energy flow is from high energy to low (hot to cold).

- Convection - Heat transfer by convection is the energy transfer of heat by air, water, or any other fluid to and object. It includes energy transferred by random molecular motion as well as energy transferred by the bulk motion of the fluid. There are two types of convecion: natural convection and forced convection. Natural convection is fluid flow caused by changes to the fluid, such as change of density or temperature variations of the fluid. Forced convection is convection that is caused by a a piece of equipment, such as a pump or a fan.

Phase of the Process Fluid - The phase within a unit is an important consideration in the selection of the heat exchanger type. Liquid phase fluids are generally the simplest to deal with. The high density and the favorable values of many transport properties allow high heat transfer coefficients to be obtained at relaticely low pressure drops.

Fin Surface Geometry - Transferring heat from a hot fluid into a colder fluid through a tube wall is the reason to use finned tubes. The fluid with the lowest heat transfer coefficient will dictate the overall heat transfer rate. When the heat transfer coefficient of the fluid inside the tube is several times larger than that of the fluid outside the tube, the overall heat transfer rate can be greatly improved by increasing the outside surface area of the tube. Finned surfaces are manufactured by extruding, welding, or wrapping a thin metal sheet on a surface. Fins enhance heat transfer from a surface by exposing a larger surface area to convection and radiation. There are many different types of fins.

- Longitudinally

- Transverse

- Herringbone

- Louvered

- Offset Strip

- Perforated

- Rectangular

- Serrated

- Triangular

- etc.