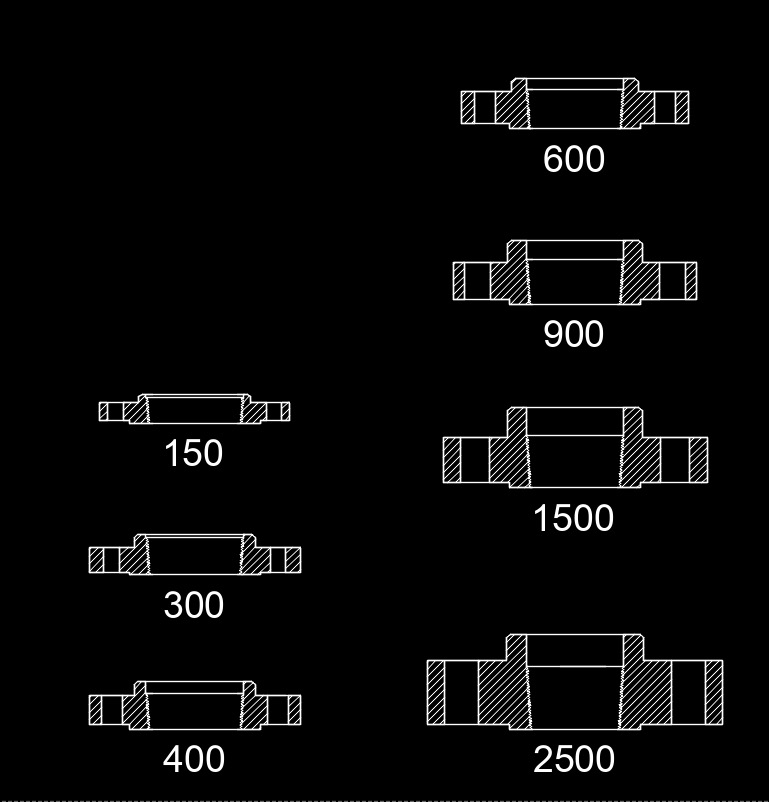

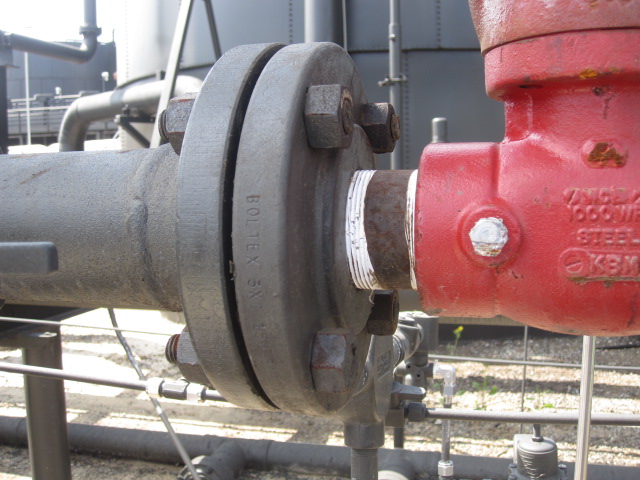

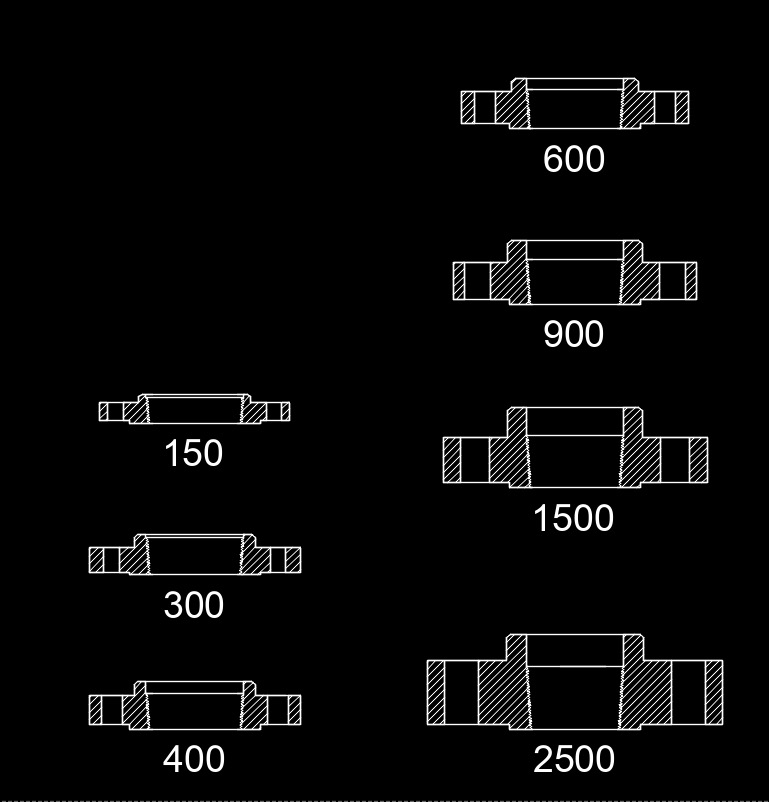

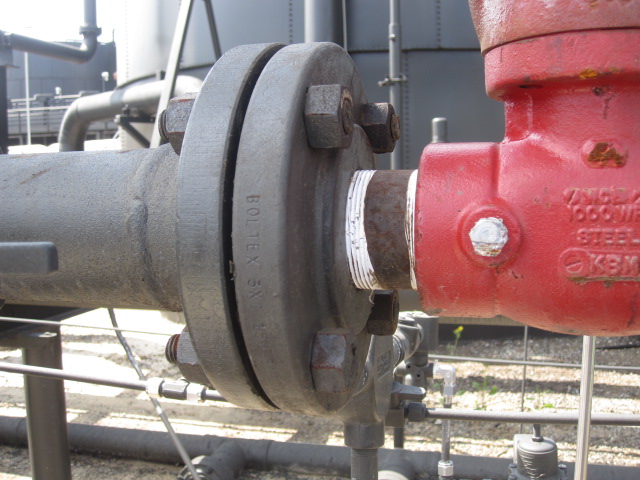

The threaded flange, abbreviated as TRHF, is similar to a slip-on flange, but has internal threads. It is normally used for low pressure and not used where temperature or stress is very high. This flange has a raised face.

The threaded flange, abbreviated as TRHF, is similar to a slip-on flange, but has internal threads. It is normally used for low pressure and not used where temperature or stress is very high. This flange has a raised face.

Threaded Flange Index

Threaded Flange Advantages and Disadvantages

|

|---|

| Advantages | Disadvantages |

|---|

- Threaded flanges are relatively easy to install without the need for welding. This can be advantageous in situations where welding is impractical or undesirable.

- The absence of welding makes threaded flanges suitable for applications where welding is not permitted or is considered a safety hazard.

- Threaded flanges are commonly used for small diameter pipes, and they provide a convenient and cost effective solution for these applications.

- Threaded connections allow for easy disassembly and reassembly of the piping system. This can be beneficial for maintenance, repairs, or modifications to the system.

- Threaded flanges are suitable for low pressure applications where the threaded connection provides sufficient strength.

|

- Threaded flanges are generally not recommended for high pressure and high temperature applications. The threaded connection may not provide the same level of strength as welded connections.

- The threaded connection may be more prone to leakage compared to welded connections, especially if proper sealing techniques are not employed.

- Achieving precise rotational alignment during installation can be challenging with threaded connections. This can be a limitation in applications where precise alignment is critical.

- Threaded connections are susceptible to loosening due to vibration. In high vibration environments, additional measures such as thread locking compounds may be required to prevent unintentional loosening.

- Threaded flanges are typically used for smaller diameter pipes. For larger diameter pipes or high pressure systems, other types of flanges may be more appropriate.

- The threaded connection may not provide the same level of structural integrity as welded connections, making threaded flanges less suitable for applications with high structural demands.

- Threads can wear over time, leading to potential issues with the connection. Care must be taken during installation and maintenance to avoid thread damage.

|