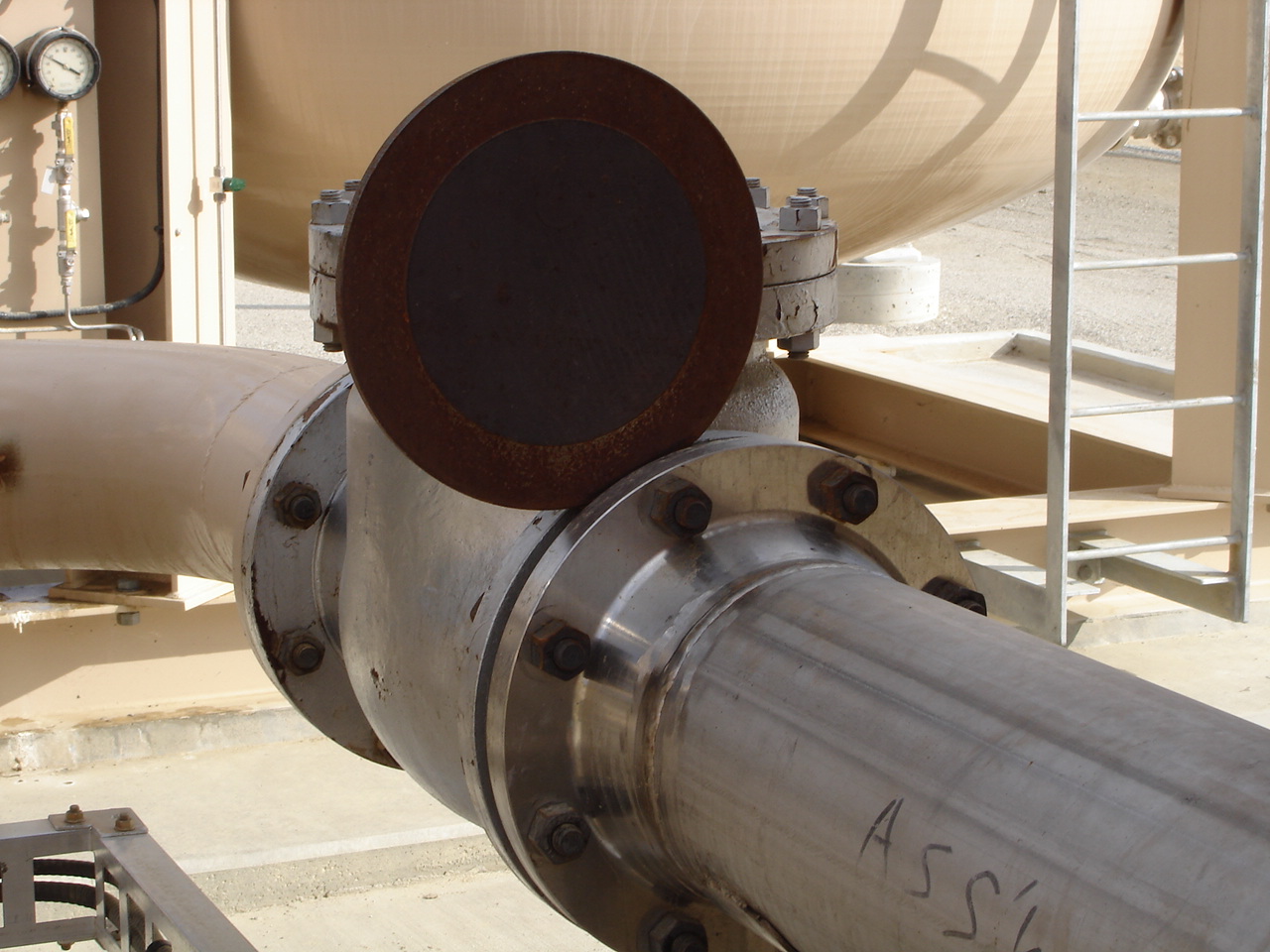

Spectacle Blind

The primary purpose of a spectacle blind is to provide a safe and convenient way to isolate a section of a pipeline for maintenance, inspection, or repair. It's important in situations where simply closing a valve or using a blind flange is not practical or safe. The advantage of a spectacle blind is that it can be easily rotated to open or close the pipeline, making it a versatile and reliable solution for temporary isolation.

In addition to its isolation function, spectacle blinds are also used to prevent foreign materials from entering a pipeline during construction or maintenance activities. They are typically made from materials that are compatible with the pipeline's contents, such as carbon steel, stainless steel, or other corrosion resistant alloys.

Spectacle Blind Design Classification

Ring Spacer - Ring spacers are bored to the matching pipe ID and are the same thickness as the "single blind" that it replaces. When removing a "single blind", either the flange and associated piping must be pulled together to seal the line, or a "ring spacer" must be installed to fill the gap. Thick single blinds or rigid piping systems normally require ring spacers.

Single/ Line Blind or Blank - A positive shut-off device normally installed adjacent to, or in conjunction with, a valve. Their purpose is to prevent accidental flow through a pipeline to a vessel. With the exception of cast iron, plastic, or fiberglass services, they are not drilled with bolt holes, but fit inside the bolt circle of mating flanges. Pipeline blinds or blanks are not the same as bolting blind flanges. Single blinds use standard gaskets.

- A combination of a "single blind' and a "ring spacer" can be fabricated for field convenience as a single unit. Weight consideration and the associated difficulty of handling heavy pieces in the field are a primary consideration in specifying a "spectacle blind" or a combination of blinds. Spectacle blinds are meant to be rotated to change blind/spacer orientation.

Spectacle Blind - A spec blind is a combination of a ring spacer and single blind. They are usually permanently installed in a piping system and rotated as needed.

Test Blank - A test blank is specially designed blank used for hydrostatic or other incompressible fluid testing purposes only. Their advantage is cost and weight savings since higher allowable stress values (or lower safety factors) are used in their design.

Vapor Blind - Similar to a "single blind", but thinner, normally 1/8" (3mm) to 5/16" (8mm) thick. These are positive sealing devices intended to prevent accidental flow or leakage of vapors into a pipeline or vessel, usually while the system is in service. Vapor blinds are not to be subject to differential pressure.

Spectacle Blind Specification

The specification that determines the dimensions of a spectacle blinds is ASME B16.48 - Line Blanks. A line blank conforming to this standard will be marked in the following way:

- B16

- Nominal pipe size (NPS)

- Nominal pressure class

- Material

- Manufacturer's name

- If RTJ, the ring number

Spectacle Blind Advantages and Disadvantages | |

|---|---|

| Advantages | Disadvantages |

|

|

Spectacle Blind Standards

-

- ASME B16.5 - Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard

- ASME B16.20 - Metallic Gaskets for Pipe Flanges: Ring-Joint, Spiral-Wound, and Jacketed

- ASME B16.47 - Large Diameter Steel Flanges: NPS 26 Through NPS 60 Metric/Inch Standard

- ASME B16.48 - Line Blanks

Spectacle Blind Datasheets |

|||

| Class | Spectacle Blind Raised or Flat Face | Class | Datasheets |

| ANSI 300 | Spectacle Blind - ANSI Class 300 (in) | ANSI 75 - 2500 | Pipe Flange Datasheets |

| ANSI 600 | Spectacle Blind - ANSI Class 600 (in) | ||

| ANSI 900 | Spectacle Blind - ANSI Class 900 (in) | ||

| ANSI 1500 | Spectacle Blind - ANSI Class 1500 (in) | ||

| ANSI 2500 | Spectacle Blind - ANSI Class 2500 (in) | ||

Tags: Pipe Fitting Pipe Flange Valve Pipeline